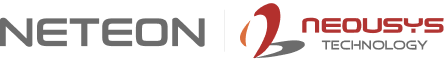

The Municipal Automation Challenge: Computing That Survives the Streets

Objective: Municipal street cleaning demands computing platforms that survive extreme temperature swings, pressurized water jets, and continuous vibration—conditions that destroy standard industrial computers within months. Shanghai's 200+ autonomous cleaning vehicles demonstrate that success requires purpose-built platforms for uncontrolled outdoor environments.

Core Failure Modes in Autonomous Cleaning Operations

1. Environmental Ingress: When Dust and Water Become Circuit Killers

Municipal cleaning vehicles encounter dense dust clouds, high-pressure water spray, and humidity extremes. Standard IP54 industrial computers fail within weeks.

The Failure:

Dust particles under 50 microns penetrate standard enclosures through cooling fan intakes and connector gaps, creating conductive paths that short circuit boards. Water follows the same routes—humidity condensation progresses to liquid accumulation during pressure washing. This electrochemical environment corrodes solder joints and component leads. Early Shanghai deployments experienced 40% computer replacement rates within six months due to environmental damage.

The Architectural Fix: IP67 Sealed Fanless Design

Fanless architecture eliminates dust/water entry vectors entirely. Thermal management shifts to conduction cooling through sealed aluminum chassis functioning as heatsinks. All connectors use screw-lock designs with O-ring gaskets rated for IP67 immersion.

- Mechanism: Complete sealing prevents ingress regardless of particle size. Fanless operation removes forced-convection pathways. Conformal coating on circuit boards provides secondary humidity protection.

- Result: Zero environmental failures across Shanghai's 200+ vehicle fleet since 2018. Systems maintain functionality through daily water spray and dust exposure without maintenance or replacement.

2. Thermal Extremes: The Outdoor Computing Dilemma

Shanghai's subtropical climate creates challenging thermal conditions for autonomous vehicles. Winter temperatures drop to -5°C during pre-dawn deployment hours. Summer operations are far more severe—direct sun exposure combined with asphalt surface temperatures exceeding 65°C creates interior compartment temperatures reaching 55-60°C. Standard commercial platforms rated 0°C to 40°C experience immediate failure at these extremes.

The Failure:

At Shanghai's winter lows near -5°C, standard platforms experience sluggish boot times and reduced battery performance. More critically, summer heat above 50°C triggers thermal shutdowns in commercial CPUs and GPUs, ending autonomous operation mid-route. Systems continuing above 40°C rated temperature experience halved component lifespan—every 10°C increase doubles electromigration failure rates. Shanghai's sustained summer heat accelerates aging that would take years in controlled environments.

The Architectural Fix: Wide-Temperature Component Selection

Extended-temperature platforms use industrial-grade components rated for -40°C to 85°C throughout—CPU, RAM, storage, power regulation. Chassis thermal design employs large-surface-area aluminum heatsinks with direct conduction paths. Patented cassette design segregates thermal zones, preventing GPU heat from affecting CPU operation.

- Mechanism: Industrial-grade components rated for -40°C to 85°C provide thermal margin for Shanghai's -5°C to 60°C range (interior temps). Fanless chassis maximizes passive dissipation—entire enclosure functions as heatsink. Thermal segregation prevents GPU heat affecting CPU operation.

- Result: Continuous operation through Shanghai's annual temperature cycle without thermal throttling. Systems maintain performance during sustained 35-40°C summer conditions that disable commercial platforms.

3. Power Instability: When Vehicle Electrical Systems Challenge Computing Uptime

Municipal vehicles experience constant transients—ignition cranking sags below 8V, alternator spikes exceed 32V, emergency stops terminate power instantly. Standard platforms cannot tolerate these events.

The Failure:

Ignition cranking sags voltage below 8V, triggering immediate shutdown and corrupting active file writes. Alternator spikes above 30V destroy input stage components. Even clean shutdowns present challenges—platforms require 5-10 seconds for controlled sequences, but vehicle power-off is instantaneous. Early deployments showed 15-20% of systems requiring weekly manual recovery from file system corruption.

The Architectural Fix: SuperCAP UPS and Wide-Input Protection

Supercapacitor-based UPS provides instant power backup during transients. Wide-range DC input (8-35V) tolerates voltage sags and spikes. Ignition power control enables controlled shutdown when vehicle power terminates.

- Mechanism: Supercapacitors discharge instantly when voltage sags, maintaining stable power through multi-second transients. Wide-input protection absorbs spikes to 35V. Ignition monitoring triggers shutdown sequences with sufficient SuperCAP reserve for clean file system closure.

- Result: Zero power-related failures across deployed fleet. Systems survive ignition events and unexpected disconnection without corruption or manual recovery.

Technical Platform Specifications

| Environmental Capability | Specification | Engineering Benefit |

|---|---|---|

| Ingress Protection | IP67 (dust-tight, 1m water immersion) | Survives pressure washing and dust storms without component damage |

| Operating Temperature | -40°C to 85°C platform rating (-13°F to 185°F) | Handles Shanghai's -5°C to 60°C (interior) range with substantial thermal margin |

| Shock Resistance | MIL-STD-810G (50G, 11ms half-sine) | Withstands pothole impacts and curb strikes during navigation |

| Vibration Tolerance | MIL-STD-810G (5 Grms, 5-500 Hz) | Continuous operation during vehicle movement and brush vibration |

| Power Input Range | 8-35V DC wide-input | Tolerates ignition sags and alternator spikes without shutdown |

| GPU Support | Dual NVIDIA RTX 30/20 series | Multi-camera AI inference for obstacle/traffic/pedestrian detection |

| Network Connectivity | PoE+, 5G/4G/WiFi 6, GPS | Real-time fleet tracking and camera system integration |

| Power Backup | SuperCAP UPS | Maintains uptime during transients, prevents corruption on power loss |

Implementation Checklist: AMR Platform Integration

| Engineering Advantage (Pros) | Implementation Constraint (Trade-offs) |

|---|---|

| IP67 sealing eliminates maintenance – fanless design prevents dust/water ingress requiring monthly cleaning | Limited thermal headroom – fanless cooling restricts peak GPU power to 75W designs |

| Wide-temperature enables year-round deployment – -40°C to 85°C rating provides thermal margin for Shanghai's extreme summers | Extended-temperature adds 20-30% cost – industrial-grade parts cost more than commercial equivalents |

| SuperCAP UPS prevents corruption downtime – instant backup eliminates weekly manual recovery | SuperCAP requires periodic replacement – capacitors degrade over 5-7 years |

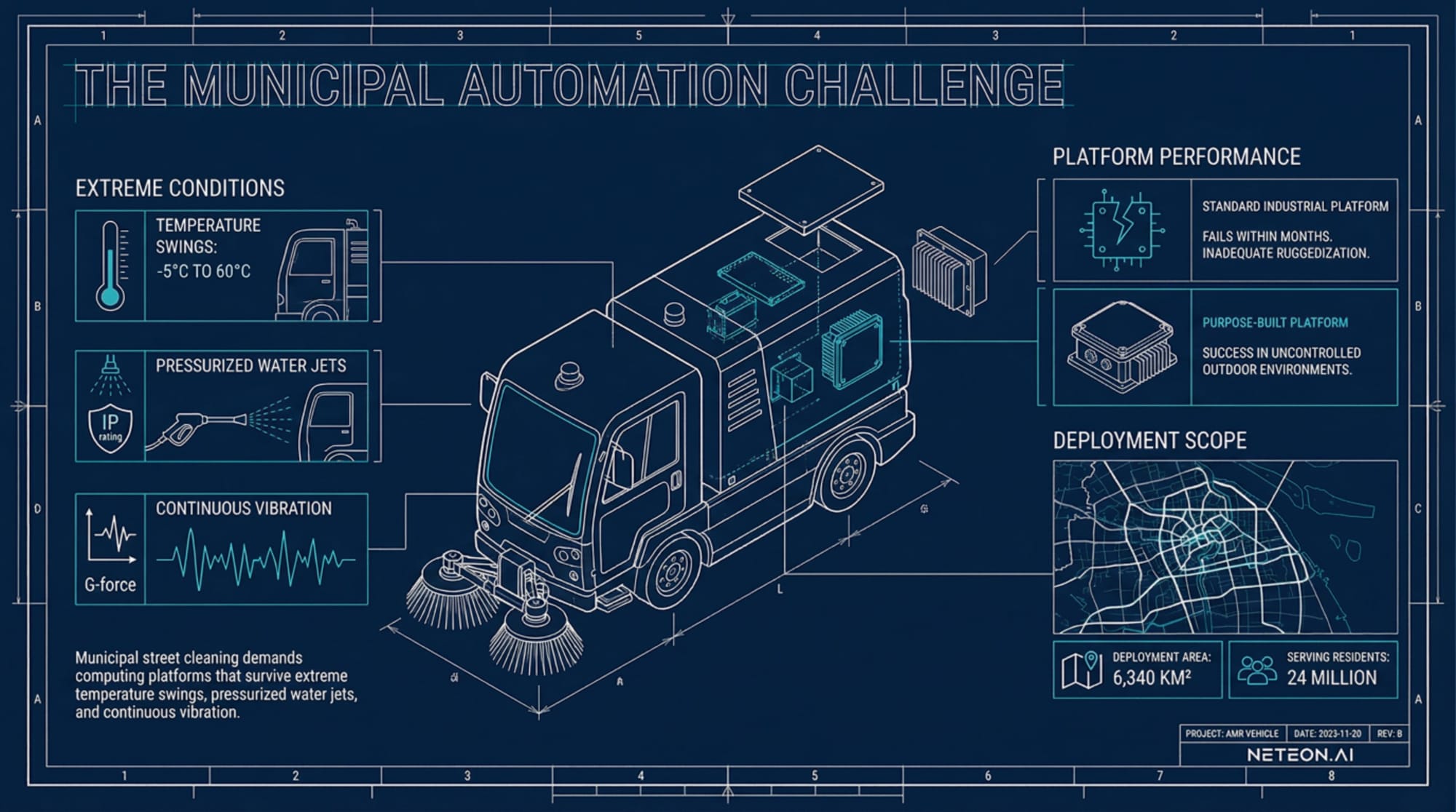

Real-World Deployment: Shanghai Municipal Fleet

Shanghai deployed autonomous street cleaning vehicles powered by ruggedized GPU platforms beginning in 2018, now operating 200+ vehicles across 6,340 km² serving 24 million residents. Each vehicle operates 6-8 hour nighttime shifts with GPS-aided navigation (±0.5m accuracy), LiDAR/camera obstacle avoidance, AI traffic recognition, and autonomous parking/charging/waste disposal.

Performance Metrics:

- Zero environmental failures across 200+ vehicles since 2018

- 40% reduction in operating costs versus human-operated crews

- 95% autonomous route completion without intervention

Related Products

Nuvo-9160GC: High-performance GPU platform supporting NVIDIA RTX A6000 for maximum AI inference throughput. Features dual GPU support, 16-lane PCIe Gen4, and MIL-STD-810G ratings. Ideal for autonomous vehicles requiring real-time processing of 8+ camera streams.

POC-551VTC: Compact fanless in-vehicle computer with ignition power control, 8-35V wide-input, and CAN bus interface. Perfect for smaller autonomous platforms where computing density is the limiting factor.

Contact Us

For more insights on autonomous vehicle computing and smart city infrastructure, follow Neteon on LinkedIn at https://www.linkedin.com/showcase/neteon-edge-ai/. To discuss your edge computing requirements, contact us at www.neteon.net or email [email protected].