TLDR: Transforming Humanitarian Demining Through Autonomous Technology

Humanitarian demining organizations face an urgent crisis: 6,279 people were killed or injured by landmines in 2024, with civilians accounting for 90% of casualties and children representing nearly half of all victims. Traditional manual landmine detection methods put human lives at constant risk while progressing slowly across contaminated terrain. An innovative autonomous landmine detection and marking vehicle addresses this challenge by deploying AI-powered robotics equipped with the SEMIL-1700GC series rugged embedded computer. This waterproof, GPU-accelerated system enables autonomous navigation, real-time magnetic detection processing, and precision paint marking that conforms to United Nations safety conventions—all while operating reliably in the harsh, unpredictable environments where landmines threaten communities.

Overview: The Escalating Global Landmine Crisis

A Humanitarian Emergency Demanding Innovation

The global landmine contamination crisis has reached critical levels. The Landmine Monitor 2025 report documented more than 6,000 incidents in 2024, including 1,945 fatalities and 4,325 injuries—the highest annual total since 2020. The human toll extends beyond statistics: children remain especially vulnerable, particularly in conflict-affected countries where displaced families return to heavily contaminated areas.

The challenge spans continents. Myanmar recorded over 2,000 incidents representing the highest national toll, while Syria faces heightened risks from unexploded ordnance following regime collapse. Traditional demining methods—relying on manual labor with metal detectors—expose workers to constant danger while advancing at painfully slow rates across contaminated regions.

The Technical Challenge: Autonomous Detection in Unstructured Environments

Landmines present unique detection challenges. Hidden beneath unstructured terrain in rural areas, hillsides, and agricultural zones, these explosives require systematic scanning across vast expanses. The Ottawa Convention established international standards mandating cleared areas be marked with distinctive white (safe) and red (danger) paint indicators—creating the need for autonomous systems that can detect, navigate, and mark simultaneously.

The solution requires sophisticated edge computing capable of processing sensor data, executing autonomous navigation algorithms, managing paint marking systems, and operating continuously in extreme environmental conditions where mission failure could prove catastrophic.

Challenge: Engineering Autonomy for Life-Saving Missions

Autonomous Navigation and Detection Integration

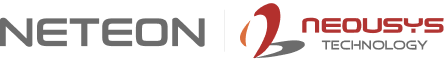

Deploying an autonomous vehicle for landmine detection demands seamless integration of multiple complex systems. The platform must autonomously navigate predetermined areas derived from satellite imagery while continuously scanning for buried threats. Magnetic sensors mounted at the vehicle's front require real-time processing to detect anomalies beneath ground surface, distinguishing actual landmines from metallic debris.

Computing Requirements:

- Processing multiple sensor streams simultaneously (cameras, LiDAR, magnetic detectors)

- Executing autonomous navigation algorithms without human intervention

- Managing real-time decision-making for obstacle avoidance

- Coordinating paint marking systems triggered by detection events

Environmental Extremes and Reliability Demands

Landmine detection vehicles operate in extreme conditions: temperature swings from scorching heat to freezing cold, constant dust and moisture exposure, severe vibration from rough terrain, and potential water immersion during river crossings.

Standard industrial computers fail rapidly here. GPU thermal throttling degrades processing when autonomous systems need consistent power. Dust infiltration causes component failure. Vibration interrupts critical operations mid-mission.

Precision Maneuvering in Confined Spaces

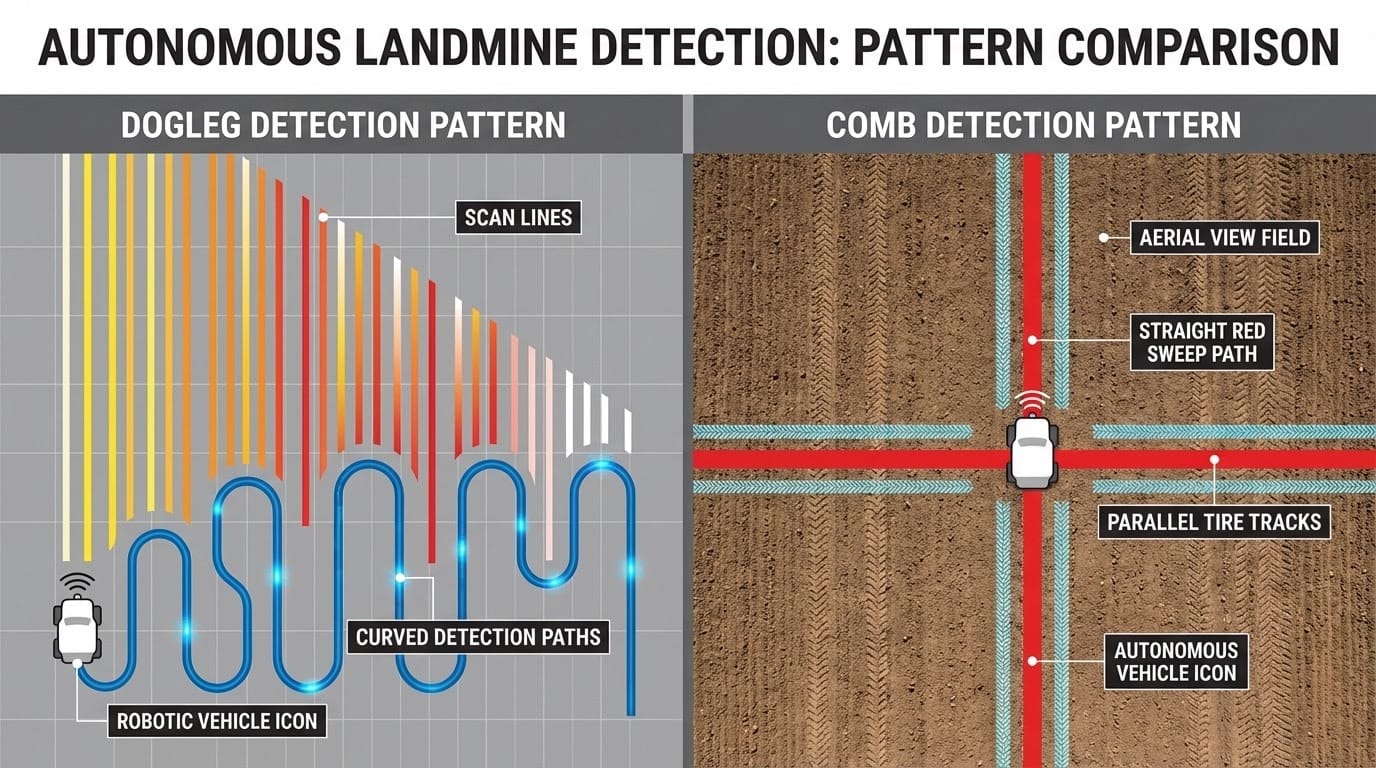

Efficient area coverage requires the vehicle to execute what operators term the "dogleg" scanning pattern. This technique involves:

- Driving to the scanning area's far edge

- Reversing along the same path while continuing detection

- Executing tight lateral movements to adjacent scanning lanes

- Repeating the pattern to achieve complete area coverage

Traditional turning circles create gaps in scan coverage—potentially leaving dangerous zones undetected. The system must track paint line positions using downward-facing cameras, distinguishing red and white markers despite variable lighting conditions including shadows, overcast skies, and intense sunlight.

Visual Line Tracking Under Dynamic Conditions

Camera-based line following for reverse-path navigation must detect painted ridges despite dramatic lighting variations, paint color changes across different surfaces, false positives from natural features, and real-time processing requirements to maintain navigation speed.

Solution: SEMIL-1700GC Powers Mission-Critical Autonomy

Waterproof GPU Computing for Extreme Environments

The SEMIL-1700GC series serves as the autonomous vehicle's computational brain, delivering GPU-accelerated processing within an IP67 waterproof enclosure. This extreme-rugged platform combines NVIDIA RTX, Tesla T4, or Quadro professional graphics cards with Intel processors, providing the computational horsepower for simultaneous autonomous navigation, sensor fusion, and computer vision tasks.

Environmental Protection:

- IP67 waterproof and dustproof certification ensures complete protection against dust ingress and water immersion up to 1 meter

- Custom-molded O-ring sealed enclosure with specialized gaskets prevents moisture penetration

- -25°C to 70°C wide-temperature operation maintains full performance across extreme thermal conditions without throttling

- Patented cassette design segregates thermal and electrical interference zones

The waterproof design proves critical during unexpected weather events or water crossings, ensuring mission continuity even when conditions deteriorate rapidly.

Autonomous System Integration Through Versatile Connectivity

The SEMIL-1700GC's extensive I/O capabilities enable seamless integration of the vehicle's sensor array and control systems:

| Interface | Application |

|---|---|

| Multiple PoE+ GigE ports | Power and connect IP cameras for line tracking and obstacle detection |

| USB 3.1 connectivity | Interface with USB cameras and peripheral sensors |

| Screw-lock connection ports | Ensure vibration-resistant connections preventing mid-mission failures |

| WiFi 6/5G/4G expansion | Enable remote monitoring and mission updates via mini-PCIe modules |

This connectivity architecture supports the vehicle's autonomous decision-making pipeline: LiDAR data for obstacle avoidance, downward cameras for paint line tracking, forward cameras for terrain assessment, and magnetic sensor streams for landmine detection—all processed simultaneously through the GPU-accelerated platform.

Real-Time AI Processing for Navigation and Detection

The NVIDIA graphics card acceleration enables real-time computer vision processing critical for autonomous operation. The system executes:

- Paint line detection algorithms identifying red and white markers across varying lighting conditions

- Obstacle recognition processing LiDAR point clouds for path planning

- Magnetic anomaly pattern recognition distinguishing landmines from metallic clutter

- Autonomous path planning calculating optimal dogleg maneuvers for complete area coverage

GPU acceleration reduces processing latency from seconds to milliseconds, enabling smooth autonomous navigation at operational speeds while maintaining detection accuracy.

Shock and Vibration Resilience for Mobile Deployment

Operating across rough terrain subjects computing hardware to continuous mechanical stress. The SEMIL-1700GC addresses this through:

- Tri-axis tested damping bracket system absorbing shock and vibration through patented mounting design

- Fanless thermal management eliminating moving parts prone to mechanical failure

- Robust M12 connectors providing industrial-grade connection stability

- Reinforced stainless steel and aluminum chassis maintaining structural integrity under impact

These engineering features enable continuous operation during traversal of rocky terrain, sudden stops, and sharp maneuvers without system interruption or component damage.

Power Management for Field Operations

Remote landmine detection missions demand reliable power management. The SEMIL-1700GC features:

- Wide-range DC input (8V-48V) accommodating vehicle electrical system variations

- Patented SuperCAP UPS preventing data loss during power interruptions

- Configurable intelligent ignition power control automating system startup/shutdown with vehicle operation

This power architecture ensures the computing platform maintains operational readiness throughout extended missions while protecting critical navigation and detection data.

Related Product Recommendations

NRU-230V-AWP: Compact AI for Next-Generation Detection Platforms

The NRU-230V-AWP represents an evolution in rugged AI computing for autonomous vehicles. Powered by NVIDIA Jetson AGX Orin delivering 275 TOPS AI inference, this IP66 waterproof platform excels in space-constrained deployments requiring advanced sensor fusion.

Why It Complements: For next-generation lightweight demining robots or multi-vehicle swarms, the NRU-230V-AWP provides exceptional AI performance in a compact form factor. Its eight GMSL2 camera ports enable panoramic vision for enhanced obstacle avoidance, while the 8V-48V wide input range and automotive-grade MCU system monitoring enhance functional safety for fully autonomous operations.

Nuvo-9000 Series: Scalable Processing for Command Control Integration

The Nuvo-9000 series fanless embedded computers deliver Intel 12th-Gen processing with extensive expansion capabilities for integrating demining vehicles into broader command and control infrastructure.

Why It Complements: When multiple autonomous vehicles require coordination through a mobile command center, the Nuvo-9000's six Gigabit Ethernet ports with PoE+, PCIe expansion slots, and hot-swappable storage enable centralized mission management. Its rugged design withstands mobile command vehicle environments while processing vehicle telemetry, mapping cleared zones, and coordinating multi-vehicle operations across contaminated areas.

Conclusion

The integration of autonomous robotics with rugged edge computing transforms humanitarian demining from a dangerous manual operation into a systematic, scalable mission. The SEMIL-1700GC's combination of waterproof GPU computing, extensive sensor connectivity, and extreme environmental resilience enables unmanned vehicles to detect and mark landmines across challenging terrain while keeping human operators safe.

As global contamination challenges intensify and funding pressures mount, autonomous detection systems offer a path toward accelerating clearance operations. Neousys Technology's proven ruggedization expertise positions these platforms as reliable partners for organizations working to protect vulnerable communities from explosive remnants of war.

For autonomous vehicle integration, technical specifications, or application engineering support, visit Neteon's solutions portfolio at www.neteon.net.