TLDR

Autonomous mining trucks eliminate human error while operating continuously in harsh desert environments exceeding 50°C. By leveraging GPS-guided navigation, LIDAR-based obstacle detection, and edge AI processing, mining fleets achieve 15-30% operational cost reduction, 10% fuel efficiency gains, and 30-40% longer tire life. Edge computing platforms enable real-time sensor fusion and predictive maintenance without cloud dependency, delivering sub-100ms latency for collision avoidance in remote mining sites.

Overview: Mining Automation Accelerates with Edge AI Computing

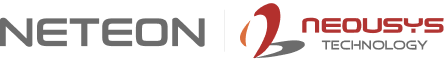

The autonomous mining truck market reached $1.5 billion in 2024 and is projected to grow at 25.1% CAGR through 2032, driven by safety imperatives and productivity demands. Mining operations face a critical challenge: haulage accounts for up to 50% of total annual costs, including fuel ($1-2M per truck annually), labor, and maintenance expenses. Traditional manually-operated haul trucks consume 150-200 liters of diesel per hour while exposing operators to hazardous conditions in remote locations.

Autonomous haulage systems (AHS) address these challenges through sensor fusion and edge AI processing. Each autonomous truck generates approximately 1GB of data per second from LIDAR, radar, cameras, and ultrasonic sensors—requiring local processing capabilities that eliminate cloud latency. As of 2024, over 2,080 autonomous haul trucks operate globally across surface mines, with major deployments in Australia's Pilbara iron ore region, Canada's oil sands, and Chile's copper mines.

The shift to autonomous operations is driven by three quantifiable benefits: eliminating human error (reducing safety incidents by 50%), enabling 24/7 operations without fatigue-related downtime, and optimizing driving patterns to reduce fuel consumption and equipment wear.

The Challenge: Processing Terabytes of Sensor Data in 50°C+ Environments

Mining sites operate in harsh desert environments where temperatures exceed 50°C while equipment endures sustained shock and vibration from unpaved haul roads. Unlike urban autonomous vehicles with reliable connectivity, remote mine sites experience intermittent or zero network coverage, requiring complete edge autonomy for safety-critical decisions.

| Technical Challenge | Mining Requirement | Why Standard Solutions Fail |

|---|---|---|

| Operating Temperature | -25°C to 70°C continuous operation | Commercial computers limited to 0°C to 60°C; thermal throttling degrades performance |

| Shock/Vibration | MIL-STD-810G compliance (5G sustained) | Standard PCs fail within 6 months; hard drives unsuitable |

| Processing Latency | <100ms for collision avoidance | Cloud latency 200-500ms; edge processing mandatory |

| Sensor I/O Density | 16+ channels (LIDAR, radar, cameras) | Traditional systems offer 8 channels; insufficient for fusion |

| Network Independence | 24/7 operation with zero connectivity | Cloud-dependent systems fail during outages |

Real-Time Sensor Fusion Requirements

Autonomous trucks simultaneously process LIDAR point clouds (1-2 million points/second), camera video (60 FPS), radar velocity data (20Hz), and GPS/RTK positioning. Fusing these heterogeneous streams requires GPU-accelerated parallel processing with specialized I/O interfaces. Fleet managers also need continuous monitoring of 100+ vehicles for predictive maintenance—detecting vibration, temperature, and diagnostic anomalies before failures occur.

The Solution: Edge AI Platforms Enable Autonomous Fleet Operations

Autonomous mining systems deploy rugged edge computing platforms directly on each vehicle, processing sensor data locally while coordinating fleet operations through centralized control centers.

Onboard Edge Computing Requirements

Each autonomous truck requires industrial-grade computing meeting these specifications:

| Component | Specification | Technical Rationale |

|---|---|---|

| Processor | Intel Xeon/Core i7/i9 (8+ cores, 2.5+ GHz) | Multi-threaded sensor fusion; concurrent LIDAR/camera/radar processing |

| GPU | NVIDIA RTX 30/20 series or Tesla/Quadro | Parallel AI inference (5-10 TOPS minimum); object detection and path planning |

| Memory | 32-64GB DDR4 ECC | Point cloud buffering; AI model loading; redundant processes |

| Storage | 512GB-1TB NVMe SSD | Vibration-resistant solid-state; fast sensor data logging |

| I/O | 8+ USB3.1, 4+ GigE PoE+, CAN, RS-232/485 | LIDAR (GigE), cameras (USB3), vehicle telemetry (CAN) |

| Thermal | Fanless heat sink OR segregated zones | Dust prevention; -25°C to 70°C operation |

| Ruggedization | MIL-STD-810G; M12 connectors | Vibration damping; screw-lock prevents disconnection |

| Power | 9-36V DC; SuperCAP UPS | Vehicle compatibility; graceful shutdown protection |

Sensor Fusion and Obstacle Detection

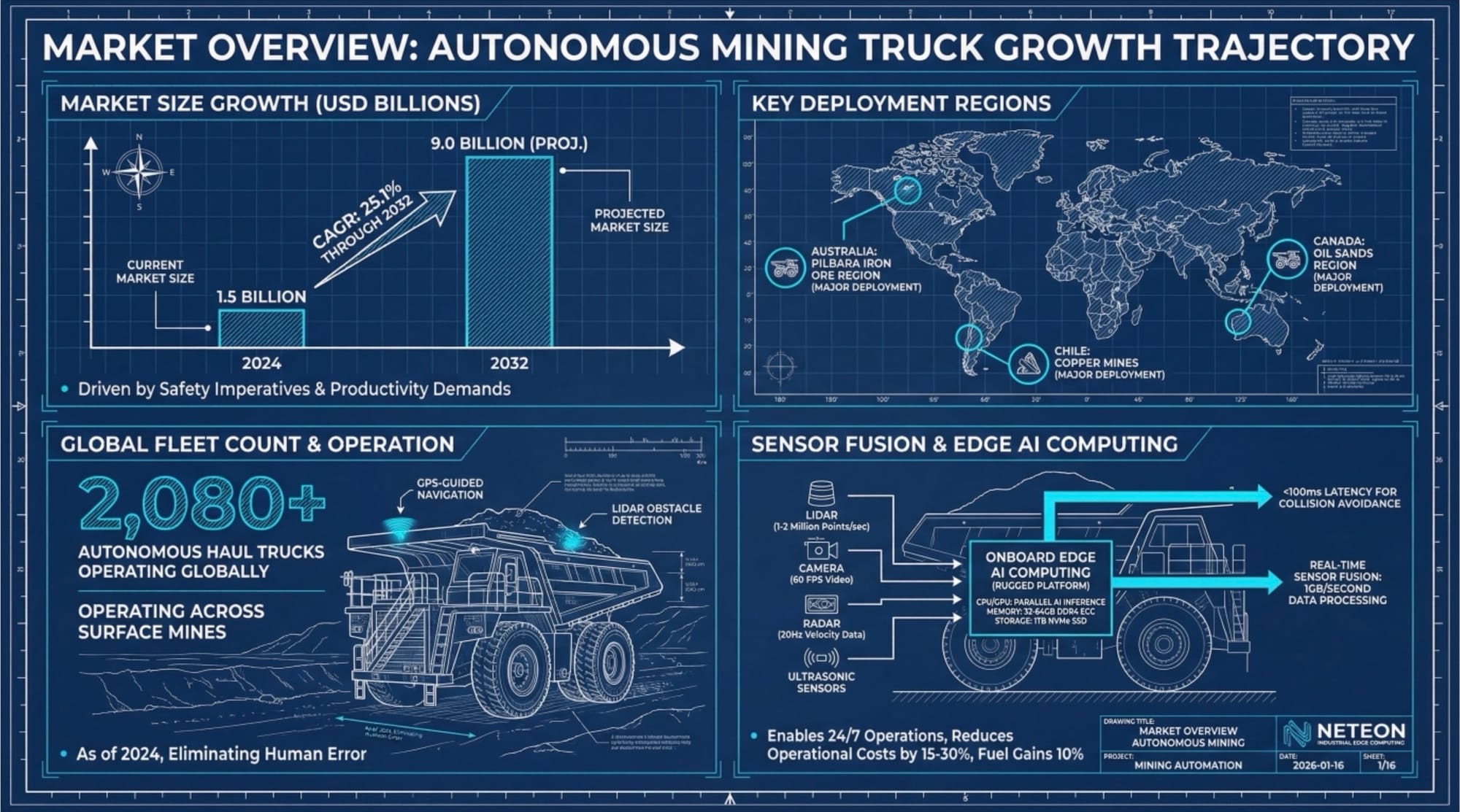

Edge platforms run real-time AI models achieving <62ms end-to-end latency:

- LIDAR: GPU-accelerated point cloud filtering for 360° obstacle mapping (10Hz)

- Camera Vision: YOLOv4/v8 object detection at 30-60 FPS

- Radar: Doppler velocity tracking for moving objects

- GPS/RTK: Centimeter-accurate waypoint navigation

Fleet Coordination

Central systems optimize operations through dynamic dispatching (load balancing), route optimization (traffic/road conditions/efficiency), and predictive analytics (edge-processed diagnostics predict failures 72+ hours ahead).

Performance Data: Manual Operation vs. Autonomous Haulage Systems

Mining companies deploying autonomous fleets report measurable improvements across operational metrics:

| Metric | Manual Operation | Autonomous Haulage | Delta |

|---|---|---|---|

| Operating Cost Reduction | Baseline | 15-30% lower | -15% to -30% |

| Fuel Efficiency | Baseline | 3-15% improvement | +3% to +15% |

| Equipment Uptime | 85-90% | 95-99% | +5% to +10% |

| Tire Lifespan | Baseline | 30-40% longer | +30% to +40% |

| Safety Incidents | Baseline | 50% reduction | -50% |

| Operational Hours | 16-18 hrs/day (shifts) | 24 hrs/day (continuous) | +33% |

| Maintenance Downtime | Baseline | 50% reduction | -50% |

| Processing Latency | N/A (human reaction ~250ms) | <100ms (edge AI) | 60% faster |

Why These Improvements Occur:

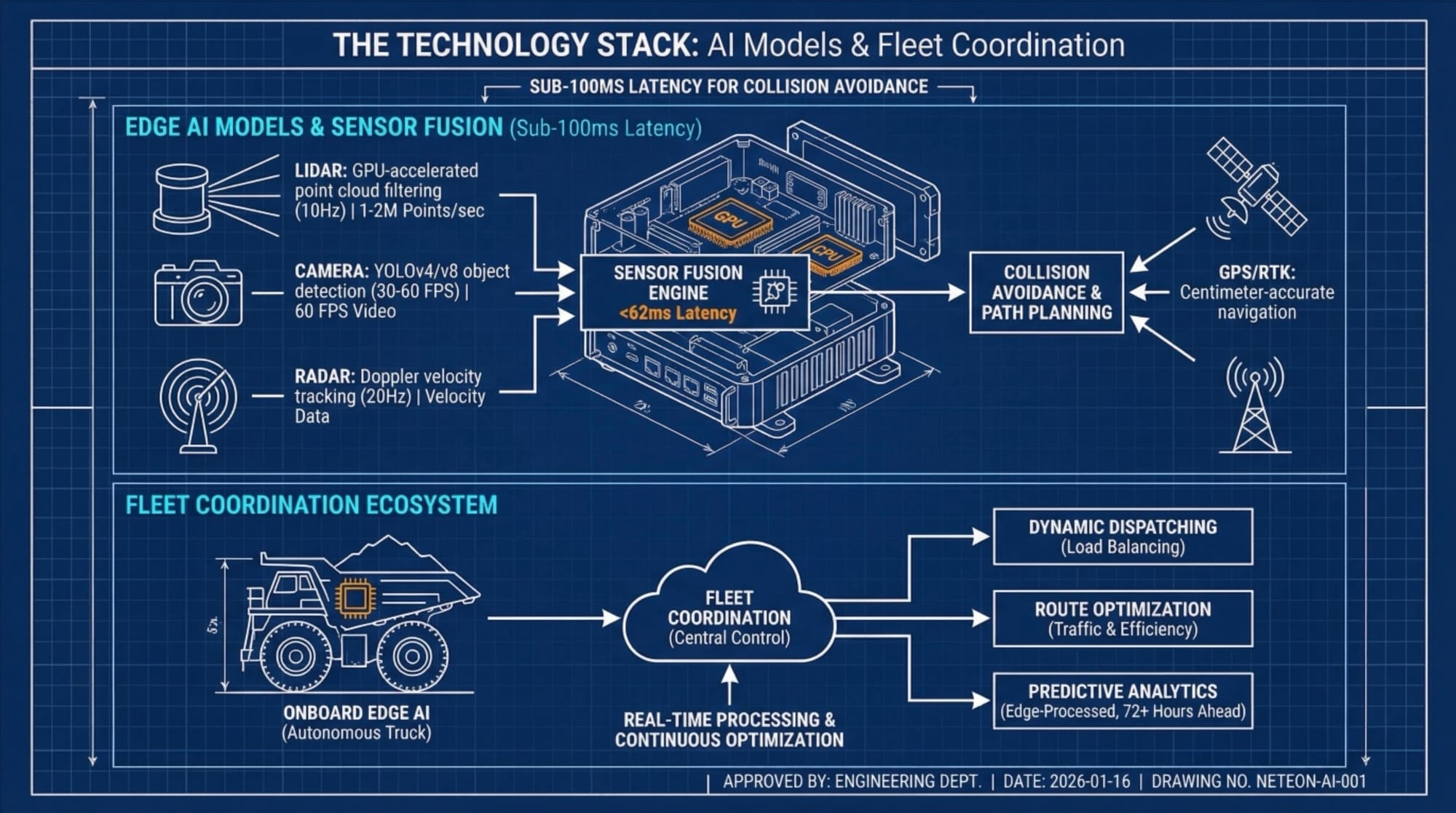

The 15-30% cost reduction stems from eliminating operator salaries (~$100K+ annually per truck), reduced fuel consumption through optimized acceleration/braking profiles, and lower maintenance costs from smooth driving patterns. Autonomous systems maintain constant speeds and avoid full stops through coordinated traffic management, reducing brake wear and tire scrubbing. Predictive maintenance enabled by continuous sensor monitoring catches small issues before major failures, cutting unplanned downtime by 50%.

Rio Tinto's autonomous fleet in Australia reports $100M+ annual savings from fuel efficiency gains, reduced maintenance costs, and productivity increases. Caterpillar's Command for Hauling customers achieve 20% operational expense reduction and 30% productivity gains across hundreds of deployed vehicles.

Related Products Recommendation

Nuvo-9160GC Rugged GPU Computer: Industrial-grade platform supporting NVIDIA RTX 30/20 series GPUs with MIL-STD-810G certification for shock/vibration resistance. Features 9-36V DC input, -25°C to 70°C operation, and 8x USB3.1 ports with PoE+ Ethernet for camera integration. Ideal for semi-autonomous haul trucks requiring real-time object detection with GPU acceleration up to 200W TDP.

Nuvo-10108GC Extreme Rugged GPU Computer: IP67-rated fanless platform with patented cassette thermal design supporting up to dual RTX 30 series GPUs. Includes SuperCAP UPS for power fault protection and M12 X-coded Ethernet for mining-grade connectivity. Designed for fully autonomous systems operating in 50°C+ desert environments with zero-maintenance fanless cooling.

Conclusion: Edge AI Transforms Mining Operations with Measurable ROI

Autonomous mining trucks represent a proven technology delivering 15-30% operational cost reduction through continuous 24/7 operations, optimized fuel consumption, and predictive maintenance. Edge computing platforms eliminate cloud dependency, processing terabytes of LIDAR, radar, and camera data locally with sub-100ms latency for collision avoidance in remote mining environments. With over 2,000 autonomous trucks deployed globally and 50% safety incident reduction, the technology has moved beyond pilot programs to become an industry standard in Australia, Canada, and Chile.

As mining companies face pressure to improve sustainability, reduce carbon emissions, and enhance worker safety, autonomous haulage systems powered by edge AI offer a clear path forward. The proven ROI period of 3-5 years, combined with regulatory incentives for automation in emerging mining regions, positions autonomous fleets as the future of efficient, safe, and cost-effective mining operations.

For more insights on edge computing in industrial automation and autonomous vehicle systems, follow Neteon on LinkedIn. To discuss your edge computing requirements for mining applications, contact us at www.neteon.net or email [email protected].