The Engineering Challenge: Multi-Point Inspection at Production Line Speed

Objective: Modern beverage bottling lines demand automated systems that simultaneously validate fill levels, detect lid placement errors, identify label misprints, and flag fluid impurities—all at 400 bottles per minute in environments with constant vibration and elevated ambient temperatures.

Multiple synchronized cameras must capture clear images while mounted to vibrating conveyor infrastructure. The controller must process multi-stream data in real-time, register faulty bottle positions, and transmit elimination commands wirelessly to downstream QA stations—all within a compact DIN-rail form factor that survives thermal and mechanical stress.

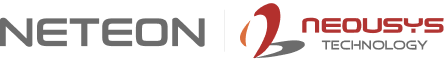

Three Critical Design Barriers in Production Line Vision Systems

1. Thermal Density: Compact Processing in High-Temperature Zones

Production lines concentrate heat-generating equipment in confined spaces. Conveyor motors, lighting arrays, and sealing machinery create ambient temperatures exceeding 50°C. When a vision controller must fit DIN-rail mounting constraints while running AMD Ryzen processors and Radeon Vega GPUs (3.3 TFLOPS FP16), thermal physics becomes the primary design barrier.

The Failure: Standard fanless systems rely on passive heat spreaders sized for enclosure surface area. At 60°C ambient, a processor running at 85°C has only 25°C of thermal headroom—insufficient for sustained compute loads. Throttling begins, frame processing drops below required rates, and bottles pass uninspected.

The Architectural Fix: True Wide-Temperature Thermal Design

The POC series implements thermal segregation up to 70°C through chassis architecture rather than component derating.

- Mechanism: Copper heat pipes directly contact CPU and GPU die surfaces, transferring thermal energy to an extended aluminum chassis functioning as the heat sink. Internal airflow channels leverage convection even in sealed enclosures.

- Result: Sustained processing at 400 bottles per minute without throttling, even when mounted adjacent to sealing equipment at 65°C ambient.

2. Vibration-Induced Camera Misalignment: The Registration Problem

Conveyor systems generate continuous vibration at 20-60 Hz as bottles transition between belt sections and guide rails. When cameras detect defects by comparing captured images to reference templates, even sub-millimeter positional shifts create false positives or false negatives.

The Failure: Controllers mounted to conveyor frames experience full vibration amplitude. Camera lenses shift relative to mounting points. USB cables experience fretting corrosion at connector interfaces as micro-movements degrade contact resistance. After 10⁶ vibration cycles (approximately one month of operation), camera-to-controller connectivity becomes intermittent.

The Architectural Fix: Patented Damping Bracket System

The POC series employs mechanical isolation at the component level.

- Mechanism: Patented damping brackets use elastomeric isolators tuned to attenuate 20-60 Hz frequencies by 40 dB. Internal components mount to a secondary chassis that floats within the main enclosure. Cable strain reliefs distribute stress across connector bodies rather than pin interfaces.

- Result: Camera connectivity remains stable through 10⁷ vibration cycles. Image registration maintains sub-pixel accuracy for precise defect detection.

3. Cable Complexity: Four-Camera Systems in Production Environments

Detecting fill levels, lid placement, label quality, and fluid clarity requires four synchronized cameras positioned around each bottle. Traditional implementations use separate power and data cables for each camera—eight cables total, plus Ethernet and power for the controller. This creates cable management challenges in tight spaces and increases installation time.

The Failure: Eight-cable installations are error-prone during setup and maintenance. Cable bundling creates stiff trunks that resist routing through confined spaces. When maintenance requires camera replacement, technicians must trace multiple cables to identify correct pairs. Downtime extends from minutes to hours.

The Architectural Fix: PoE+ Integration

The POC series consolidates power and data transmission for compatible cameras.

- Mechanism: Four PoE+ (Power over Ethernet) ports deliver 30W per port over Cat6 cabling, sufficient for industrial cameras with integrated LED illumination. Single-cable connectivity reduces physical routing complexity. Each port maps to a specific inspection angle.

- Result: Installation time reduces by 60% compared to separate power/data cabling. Camera replacement becomes a single-cable swap, minimizing production line downtime.

Technical Comparison: Standard vs. Optimized Bottling Inspection Architecture

| Challenge | Standard Solution | POC Series Solution | Engineering Benefit |

|---|---|---|---|

| Thermal Management | Component derating, limited to 50°C ambient | Thermal segregation architecture, -40°C to 70°C range | Sustained performance in high-heat production zones |

| Vibration Resistance | System-level shock mounts | Component-level damped brackets with elastomeric isolation | 10x longer cable/connector life (10⁷ vs 10⁶ cycles) |

| Camera Connectivity | 8 cables (4 power + 4 data) per system | 4 PoE+ cables consolidate power and data | 60% faster installation, simplified maintenance |

| Processing Throughput | External GPU or distributed processing | Integrated Radeon Vega GPU (3.3 TFLOPS FP16) | Single-box solution, reduced latency |

| Form Factor | Rack-mount or panel PC | DIN-rail mountable compact design | Installs in existing control cabinet space |

| Wireless Communication | External WiFi adapter or wired backhaul | Mini-PCIe slot for integrated WiFi/4G/5G | Native wireless data transmission to QA stations |

Implementation Checklist

| Engineering Advantage (Pros) | Implementation Constraint (Trade-offs) |

|---|---|

| DIN-rail mounting fits existing control cabinets without panel modifications | Requires cabinet positioning near inspection zone for camera cable reach |

| PoE+ ports eliminate separate camera power supplies and reduce cabling complexity | Cameras must support PoE+ standard (not all industrial cameras compatible) |

| Integrated wireless module enables direct communication with downstream QA stations | Requires facility WiFi coverage or cellular signal strength at production line location |

| AMD Ryzen + Vega GPU processes 400 bottles/min with defect detection algorithms | Application software must be optimized for GPU acceleration to achieve full throughput |

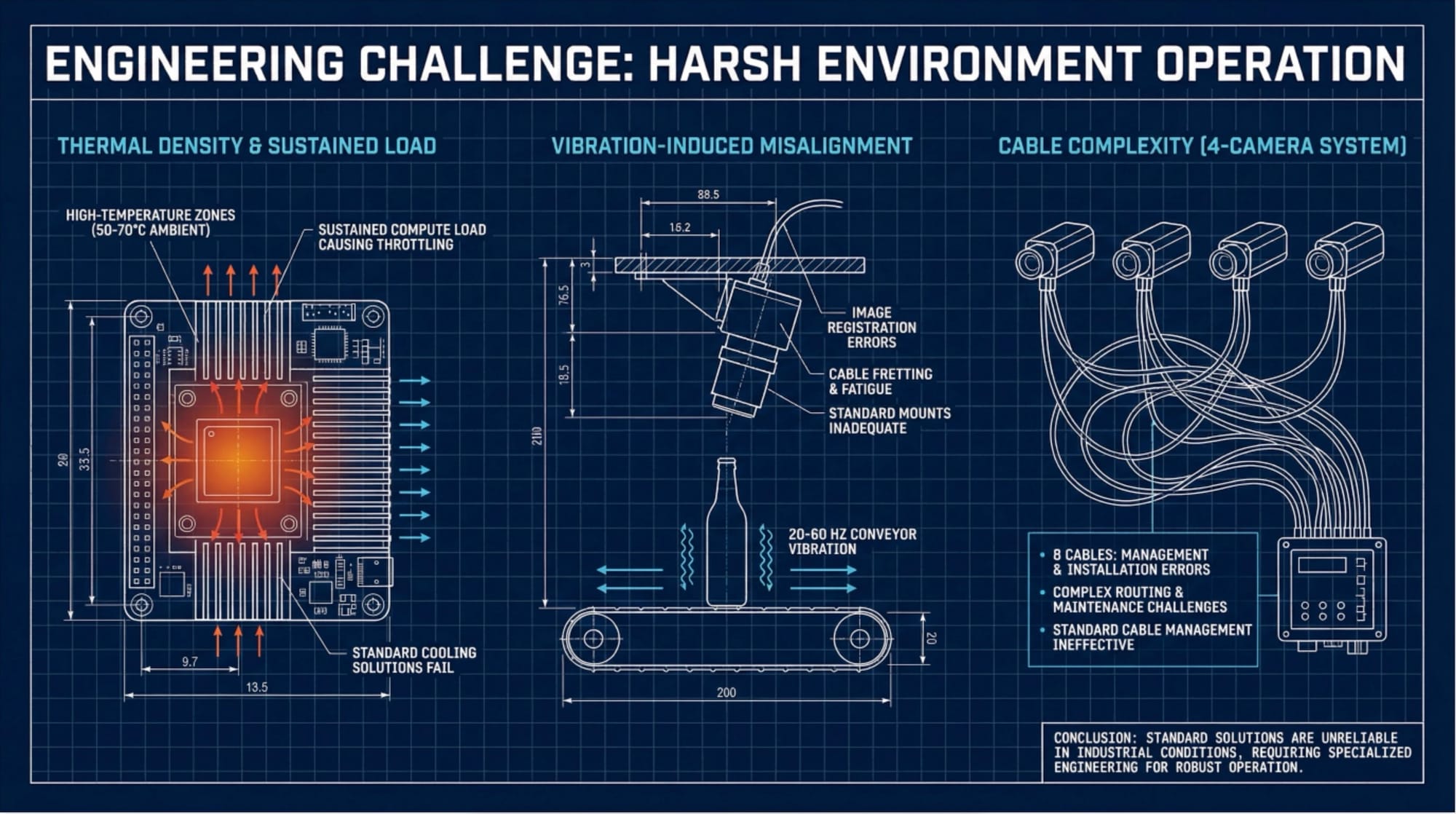

Real-World Performance: Beverage Bottling Application

A beverage manufacturer implemented the POC series with four cameras for fill level, lid placement, label quality, and fluid clarity inspection.

Measured Results:

- Throughput: 400 bottles/min sustained

- Detection: All intentional defects identified (improper fill, misaligned lids, label misprints, sediment)

- False Negatives: Zero defective bottles passed validation

- Uptime: No failures after 6 months at 60°C ambient

- Installation: 4 hours vs. 10 hours for the previous system

Related Products

Nuvo-8240GC: Industrial GPU computer with NVIDIA RTX A2000 for higher-resolution cameras or complex defect algorithms. Features eight PoE+ ports for larger inspection arrays and MIL-STD-810G certification. Operates -25°C to 60°C with 250W GPU support.

POC-551VTC: Compact fanless controller for mobile inspection applications like warehouse quality control robots or AGVs. Includes ignition power control, CAN bus interface, and 8-35V DC input for vehicle integration.

Contact Us

For more insights on automated vision inspection and industrial quality control, follow Neteon on LinkedIn at https://www.linkedin.com/showcase/neteon-edge-ai/. To discuss your production line inspection requirements, contact us at www.neteon.net or email [email protected].