TLDR: A robotics integrator developing autonomous broccoli harvesting systems encountered critical thermal throttling issues when field temperatures exceeded 50°C, causing their initial computing platform to degrade performance. By deploying the Neousys edge AI platform with true wide-temperature operation, the system achieved full processing performance under direct sunlight conditions, enabling reliable AI-powered crop detection and harvesting automation.

Overview

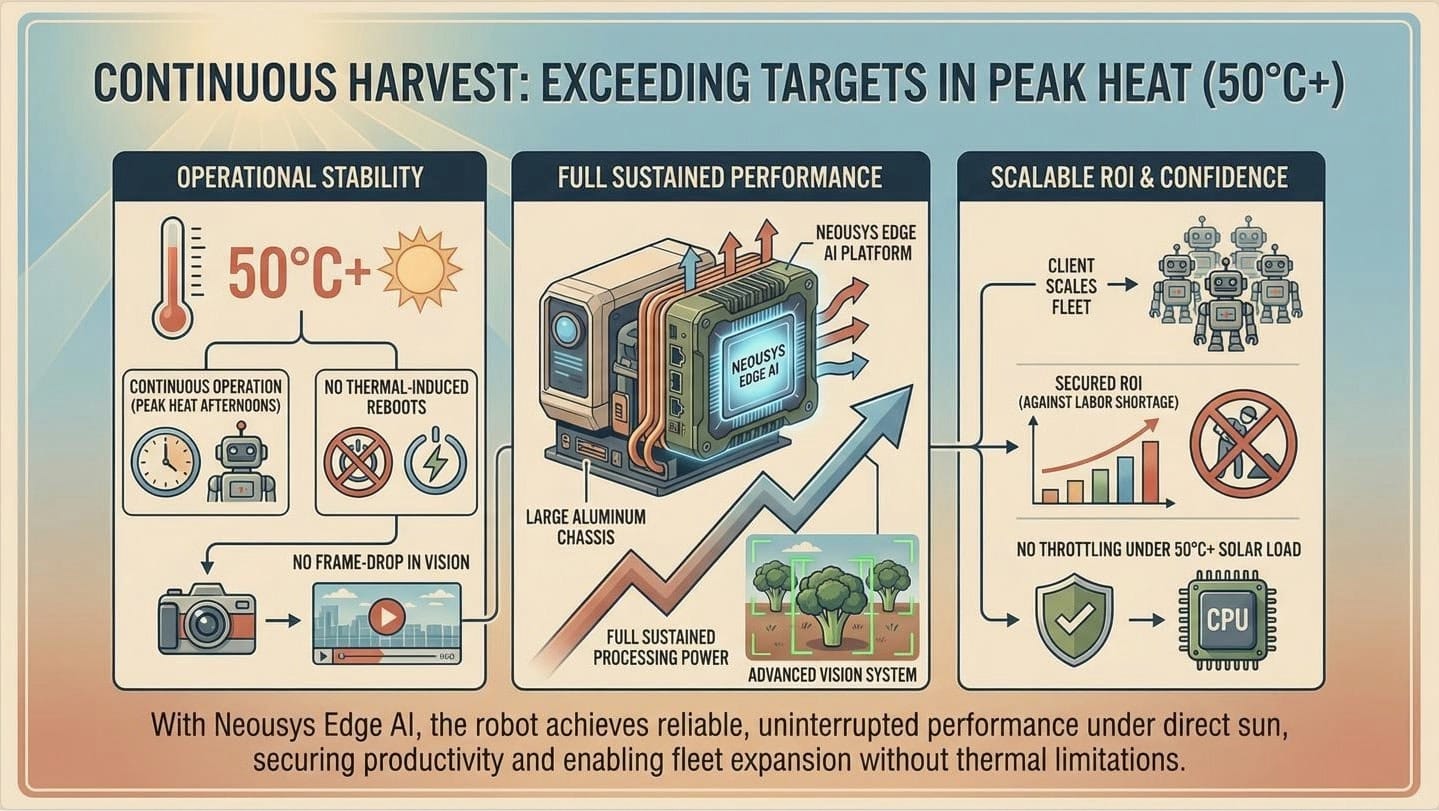

The global agricultural robotics market is expanding from USD 16.6 billion (2024) to USD 51.0 billion by 2030 (25.2% CAGR). Labor shortages during peak harvest seasons create urgent demand for autonomous systems capable of identifying and selectively picking crops.

The agriculture industry has been slow in adopting technologies into their operations, but this is steadily evolving. One client was hired to explore replacing human labor hand-picking broccoli in the field with AI robotics that can be taught to identify and pick items autonomously.

Multi-Faceted Advantages of Automation:

| Benefit Category | Impact |

|---|---|

| Worker Safety | Removes workers from harsh weather conditions |

| Injury Prevention | Eliminates grueling manual labor conditions |

| Efficiency | Continuous operation without fatigue |

| Productivity | Consistent recognition and harvesting speed |

Utilizing the Neousys edge AI platform, the robot automates the harvest of fruits and vegetables. With AI, robotics, and an advanced vision system, it identifies and locates produce ready for harvest. The system is fully customizable—the Neousys edge AI platform can be taught to adapt to specific needs including inspecting different fruits and vegetables, classifying them, putting them in boxes, palletizing the boxes, and piling them on a trailer.

By replacing workers and deploying smart machines into the field that can accurately recognize, cut, and pick off broccoli, the client could offer safety improvements while increasing efficiency and productivity.

Challenge

As with any machine deployed into the field, these robots are subject to various weather conditions. While the customer successfully developed external robotic components to endure environmental wear and tear, one critical obstacle troubled their deployment: temperature.

The Thermal Throttling Problem:

In initial sample tests with another company's computing platform, the temperature under the sun exceeded 50°C, causing the CPU to thermal throttle. This resulted in significant performance degradation—the system was hampered by the throttling CPU and was not returning the expected productivity and performance.

| Challenge | Field Condition | Result |

|---|---|---|

| Solar Heat Exposure | Temperatures exceeding 50°C under direct sunlight | CPU thermal throttling |

| Performance Degradation | Throttled processor speed | Below-expected productivity |

| System Reliability | Intermittent performance drops | Inconsistent harvesting operation |

Why Standard Computing Platforms Failed:

Many computing vendors claim operating temperatures up to 50°C, but these ratings often reflect controlled laboratory conditions rather than real-world agricultural environments where:

- Direct solar radiation creates localized hot spots exceeding ambient temperature

- Sustained operation maintains thermal load continuously

- Dust and debris reduce cooling system effectiveness

- Enclosure temperatures exceed external ambient readings

Solution

Sourcing from several vendors, the client discovered the Neousys edge AI platform that met their specifications for edge AI processing. While other vendors claimed operating temperatures up to 50°C, it was the Neousys platform that offered true wide-temperature operation.

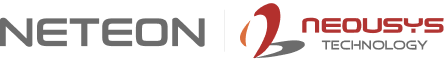

Performance Comparison: Previous Platform vs. Neousys Edge AI Platform

| Metric | Previous Platform | Neousys Edge AI Platform |

|---|---|---|

| Claimed Operating Temp | Up to 50°C | True wide-temperature operation |

| Actual Field Performance (>50°C) | Thermal throttling | No throttling |

| CPU Performance Under Sun | Degraded | Full sustained performance |

| Productivity | Below expectations | Above par |

Once installed and implemented, working under the same sunny conditions that caused the previous platform to fail, the CPU did not throttle—thanks to Neousys' unique thermal dissipation design.

Key Technical Differentiator:

The Neousys edge AI platform achieves true wide-temperature operation through a from-the-ground-up thermal design approach rather than simply rating standard components for extended temperatures. This includes:

- Patented heat-pipe thermal architecture conducting heat away from critical components

- Aluminum chassis design serving as a massive heat sink

- Fanless sealed construction preventing dust ingress while maintaining cooling

Industrial-grade component selection validated for sustained high-temperature operation

System Capabilities Enabled:

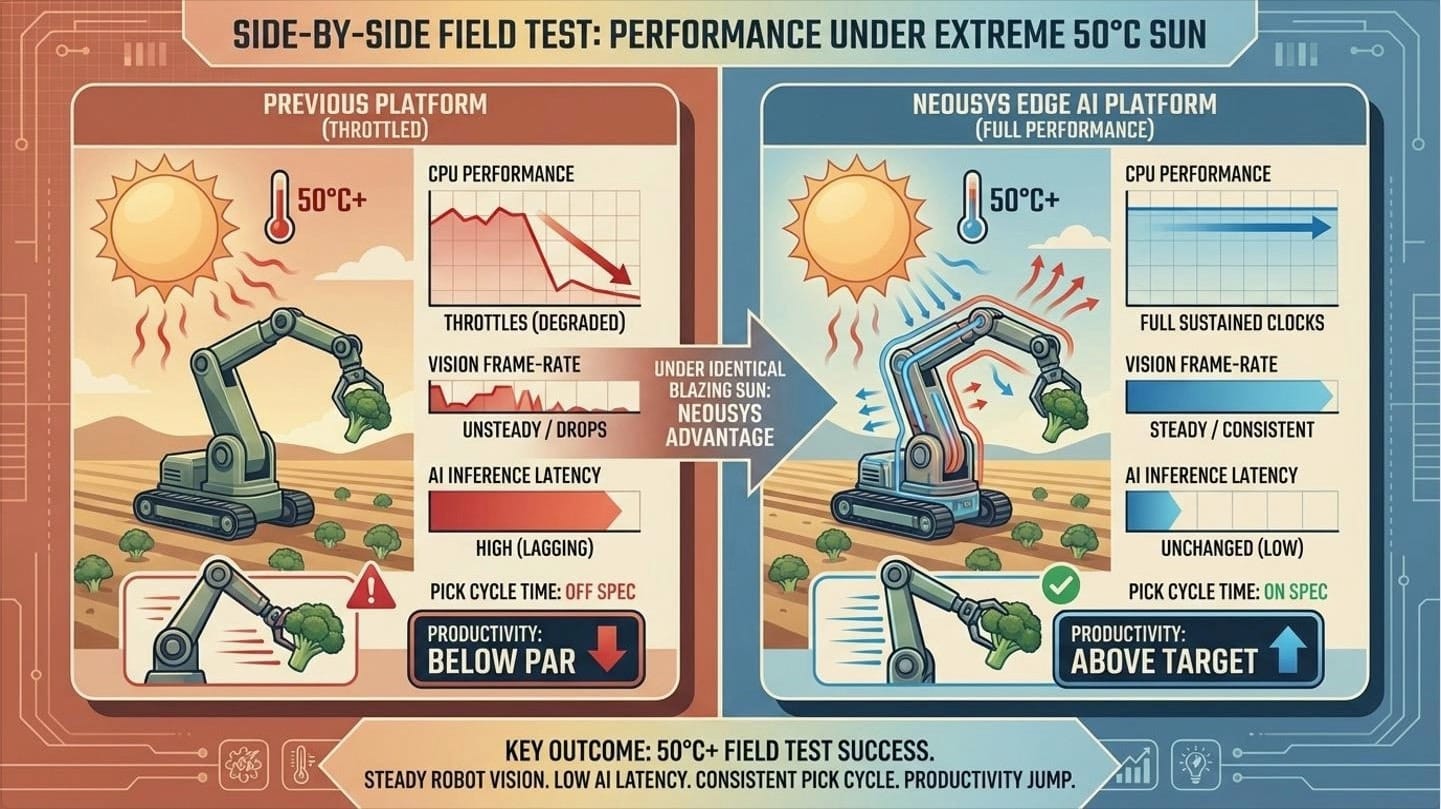

With the Neousys edge AI platform at the helm, the system in the field returned increased productivity and performed above par. The harvesting robot now reliably:

- Identifies and locates fruits and vegetables ready for harvest

- Classifies produce by size, ripeness, and quality

- Automates cutting and picking operations

- Adapts to different crop types through AI training

- Integrates with downstream sorting, boxing, and palletizing systems

Related Products

Nuvo Series Embedded Computers: The Nuvo embedded series delivers true wide-temperature operation with Intel 14th/13th/12th-Gen Core processors supporting up to 24 cores/32 threads. Compact and rugged with rich I/O connectivity including multiple PoE/USB ports for vision systems, plus COM/DIO for robotic arm control. Ideal for agricultural harvesting applications requiring sustained edge AI processing under harsh field conditions.

NRU Series NVIDIA Jetson Computers: For applications requiring compact form factors with lower power consumption, the NRU series integrates NVIDIA Jetson platforms with GMSL2 camera support. Popular with agricultural robotics clients seeking smaller footprints while maintaining AI inference capabilities for crop detection and classification.

Conclusion

The difference between "rated for 50°C" and "true wide-temperature operation" proved critical for this agricultural robotics deployment. While competitor platforms throttled and degraded under real-world field conditions, the Neousys edge AI platform delivered sustained performance that enabled the autonomous harvesting system to exceed productivity targets.

As agricultural labor shortages intensify and the robotics market expands toward USD 51 billion by 2030, reliable edge AI computing becomes the foundation for commercial-scale autonomous harvesting. Neousys' unique thermal dissipation design addresses the specific failure mode—thermal throttling under solar heat—that has historically limited agricultural AI deployments.

For technical specifications, application engineering support, or evaluation unit requests, contact our engineering team at [email protected]. Visit www.neteon.net for detailed datasheets and integration guides.