TLDR: Traditional pick-and-place robotics rely on pre-programmed coordinates for uniform objects in controlled environments, but struggle with unstructured scenes and real-time decision-making. Edge AI machine vision powered by fanless embedded computing platforms enables robotic arms to perform real-time recognition, classification, and adaptive sorting of diverse items without cloud latency. These systems must withstand thermal stress, shock, vibration, and particulate contamination while maintaining sub-100ms inference latency for production-grade automation across semiconductor inspection, metallurgy, and agricultural robotics.

Overview: From Template-Based to Adaptive Robotic Vision

The robotic vision market reached USD 3.29 billion in 2025 and is projected to grow to USD 4.99 billion by 2030, driven by AI integration and zero-defect manufacturing requirements across automotive, electronics, and semiconductor industries.

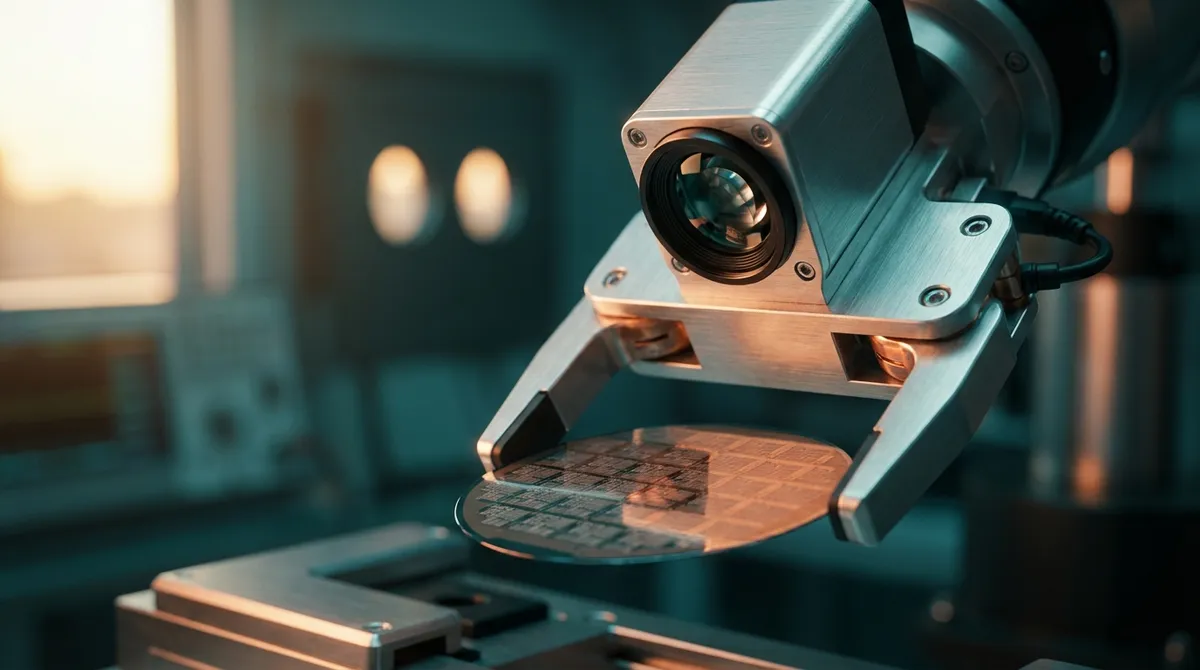

Traditional pick-and-place systems excel in structured environments—moving uniform items with pre-programmed coordinates. However, these template-based systems fail when confronted with object variation, subtle surface defects, or dynamic conditions that deviate from their programming.

Edge AI machine vision deploys embedded computing at the device level to enable real-time object recognition, defect classification, and adaptive decision-making. Rather than fixed templates, edge AI models detect subtle differences in size, shape, texture, or quality—essential for complex sorting in agriculture, recycling, semiconductor inspection, and precision manufacturing.

Challenge: Industrial Realities That Break Conventional Vision Systems

Deploying edge AI computers for machine vision in factory environments presents multiple engineering obstacles. Approximately 65% of electronics assembly lines now rely on vision-guided robotics, underscoring the critical need for systems that perform under real-world industrial stress.

Thermal Management in High-Ambient Environments

Factories often operate at elevated temperatures, particularly near furnaces or in outdoor agricultural settings. Fanless systems must dissipate heat efficiently to prevent thermal throttling during sustained GPU inference workloads.

Temperature Requirements by Application:

| Application Area | Operational Range | Survivability Range | Thermal Challenge |

|---|---|---|---|

| Semiconductor Inspection | 15°C to 35°C | N/A | High GPU load, minimal airflow |

| Metallurgy/Foundry | -10°C to 50°C | N/A | Extreme heat cycling, dust |

| Agricultural Robotics | 0°C to 40°C active harvesting | -25°C to 60°C cold-start/storage | Solar heat load on sealed enclosures |

| Sand-Blasting | 0°C to 45°C | N/A | Abrasive particle exposure |

Shock, Vibration, and Mechanical Stress

Robotic arms generate constant vibration during operation, especially in high-speed applications processing 120+ parts per minute. Edge AI computers experience sustained shock that can dislodge add-on GPU cards from PCIe slots, causing intermittent failures.

Commercial computers with standard PCIe brackets fail under sustained 3G to 5G shock loads—common specifications for mobile robotics and vehicle-mounted systems. The challenge intensifies for MIL-STD-810G/H compliance in defense or outdoor applications.

Particulate Contamination and Processing Latency

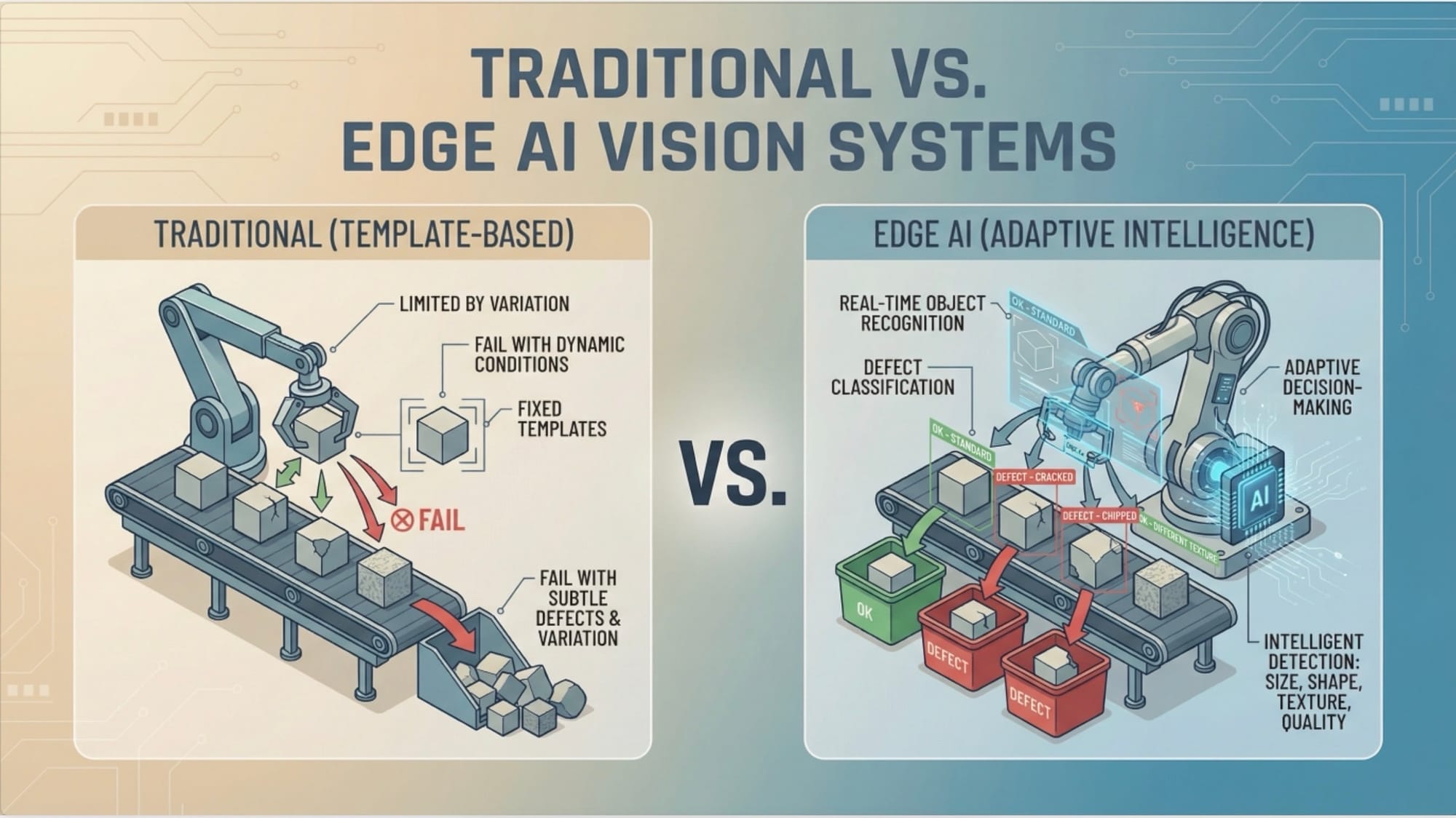

Dust, water spray, and airborne contaminants threaten both factory and outdoor deployments. Vision systems in food processing, agriculture, or heavy industry require IP65 to IP69K ingress protection. Standard industrial PCs with cooling fans draw contaminated air through the chassis, accelerating degradation.

Industrial applications demand inference latency below 50-100ms to maintain production throughput. Cloud-based vision systems introduce 150-300ms network round-trip times, making them unsuitable for real-time sorting on fast-moving conveyor lines. Edge AI computing eliminates network dependency while enabling data privacy.

Solution: Fanless Edge AI Platforms for Industrial Machine Vision

Ruggedized edge AI computing platforms address these challenges through integrated thermal design, mechanical reinforcement, sealed enclosures, and local GPU acceleration optimized for industrial vision workloads.

Engineering Solutions to Industrial Vision Challenges

| Technical Challenge | Platform Feature | Implementation Specification | Performance Outcome |

|---|---|---|---|

| Thermal Throttling | Fanless heatsink design | -40°C to 70°C operation, CPU/GPU full load | No throttling at 60°C ambient, sustained inference |

| GPU Dislodgement | Patented damping bracket | Absorbs 5G shock, secures PCIe cards | Zero disconnects in 100,000-hour MTBF testing |

| Particulate Ingress | IP65/IP67 sealed chassis | Gasket-sealed I/O, conformal coating | Operates in dusty foundries, outdoor agriculture |

| Inference Latency | On-device GPU processing | NVIDIA RTX/GTX series, Jetson modules | Sub-50ms inference, no network dependency |

| Voltage Spikes | Ignition control, wide-range DC input | 8V to 48V with transient protection | Survives mobile platform power fluctuations |

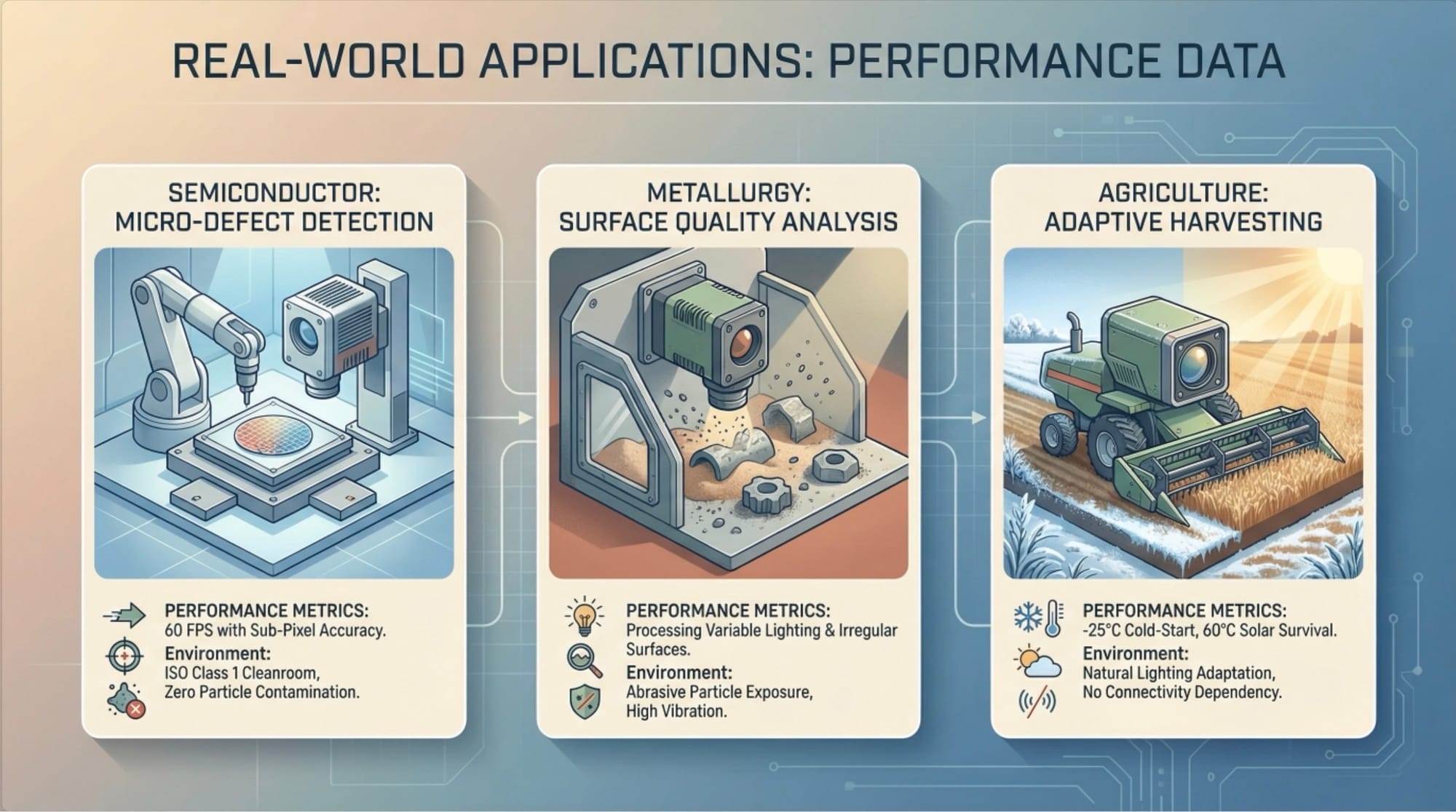

Real-World Application Performance

Semiconductor Micro-Defect Detection:

Edge AI vision systems detect micro-level faults—cracks, alignment errors, contamination—with sub-pixel accuracy at 60 FPS. Fanless systems with advanced thermal design maintain full performance in cleanrooms without particle contamination from cooling fans.

Metallurgy Surface Analysis:

In sand-blasting and metal preparation, AI vision guides robotic arms to analyze surface quality and coating uniformity. These applications require systems that withstand abrasive particle exposure while processing variable lighting and irregular surfaces that rule-based vision cannot handle.

Agricultural Adaptive Harvesting:

Outdoor agricultural robots face 0°C to 40°C active harvesting conditions, but must survive -25°C cold-start (winter storage in unheated barns) and up to 60°C solar heating on sealed enclosures. Vision systems must identify ripe produce with varying shapes, adapting to natural lighting changes. Edge AI eliminates connectivity dependency in remote field locations.

Architectural Advantages of Edge Computing

Edge processing delivers critical benefits for industrial vision: reduced data transmission (a single 4K camera at 30 FPS generates 1.5 Gbps—impractical for cloud streaming across multi-camera lines), lower latency (20-80ms on-device vs. 150-300ms cloud round-trips), enhanced privacy (sensitive manufacturing data remains on-site), and operational continuity (systems function during network outages, eliminating connectivity as a failure point).

Platform Selection Considerations

Engineers selecting edge AI platforms for robotic vision applications should evaluate:

- Thermal design validation: Documented testing at maximum ambient temperature with full CPU/GPU load, not just specification claims

- Mechanical ruggedization: Shock/vibration test data (MIL-STD-810G compliance where applicable), GPU retention mechanisms

- Ingress protection: IP ratings appropriate to deployment environment (IP54 for clean factories, IP65+ for harsh environments)

- I/O flexibility: Support for GigE Vision, USB3 Vision, CoaXPress, or GMSL2 camera interfaces based on application requirements

- Processing scalability: Upgrade path from integrated graphics to discrete GPU cards (NVIDIA RTX 4000 series, professional-grade cards)

- Power input range: Wide-range DC input (8-48V) with ignition control for mobile platforms

Related Products for Industrial Vision Applications

Nuvo-9160GC Series: GPU-accelerated edge AI platform supporting up to NVIDIA RTX 4000 series cards with patented GPU retention bracket. Features -25°C to 60°C fanless operation, 8x isolated DIO, and expansion for up to 12 GigE PoE+ ports via MezIO modules. Ideal for multi-camera factory vision systems requiring high-performance inference. Learn more at Neousys Nuvo-9160GC.

NRU-Series Jetson Computers: Compact fanless platforms powered by NVIDIA Jetson Orin modules, delivering up to 275 TOPS AI performance in sealed enclosures with flattop heatsink design. IP67-rated variants available for outdoor robotics, -25°C to 70°C operation. Features GMSL2 camera connectivity and in-vehicle power management. Optimized for mobile robotics, agricultural automation, and outdoor inspection systems. Explore at Neousys NRU Jetson Series.

Conclusion: Intelligence Moves to the Edge of Production

Edge AI machine vision transforms robotic arms from rigid automation tools into adaptive systems capable of handling the variability inherent in real-world manufacturing, agriculture, and logistics. The technology's ability to operate without cloud connectivity, combined with ruggedized hardware that survives harsh industrial environments, positions edge computing as the foundation for next-generation production automation.

As manufacturing continues its evolution toward Industry 4.0 principles—flexible production, zero-defect quality, and data-driven optimization—edge AI vision systems will become standard infrastructure rather than specialized solutions. The question for engineering teams is no longer whether to deploy machine vision, but how to select platforms that balance processing performance, environmental ruggedization, and long-term reliability.

For more insights on industrial automation and edge computing technologies, follow Neteon on LinkedIn. To discuss your edge computing requirements, contact us at www.neteon.net or email [email protected].