TLDR: Highway weight enforcement stations traditionally required trucks to exit and slow down for inspection, creating traffic bottlenalready and limited coverage. An embedded weigh-in-motion (WIM) system deployed the NRU series edge computer with GMSL cameras directly on highway surfaces to scan license plates and measure vehicle weight at highway speeds up to 100 km/h. The MIL-STD-810G compliant system operates continuously in outdoor conditions, automatically flagging overweight trucks (>80,000 lbs) for station pull-in via downstream signage—eliminating traffic disruption while increasing enforcement coverage.

Overview

The global weigh-in-motion system market was valued at $3.3 billion in 2024 and is projected to grow at 7.3% CAGR through 2034, driven by the need to protect infrastructure from overweight vehicle damage. Engineers estimate that one 80,000-pound truck causes road damage equivalent to 5,000 to 10,000 passenger cars—despite being only 9-20x heavier. This exponential damage relationship stems from the "fourth power law" where pavement wear increases with the fourth power of axle load.

Overloaded vehicles are responsible for nearly 45% of road deterioration cases, with states experiencing $12 million to $78 million annually in uncompensated road damage from overweight trucks. Traditional static weigh stations address this by randomly checking trucks, but vehicles must decelerate, exit the highway, and queue for inspection—disrupting traffic flow and limiting coverage to only a fraction of highway freight.

Modern WIM systems embed weight sensors directly into highway pavement, enabling continuous monitoring without traffic disruption. When paired with automated license plate recognition, these systems can identify non-compliant vehicles and signal them for inspection downstream. The challenge lies in deploying computer vision systems that can withstand the vibration from 18,000-pound trucks passing at highway speeds, exposure to extreme weather, and limited power availability at roadside installations.

Challenge

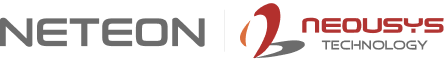

Deploying computer systems for roadside weight enforcement presents three critical engineering obstacles: environmental durability, processing requirements, and installation constraints.

Environmental Exposure and Mechanical Stress

Highway-mounted systems face extreme conditions that standard commercial computers cannot withstand. Temperatures fluctuate from freezing winters to scorching summer asphalt surfaces (potentially -40°C to +70°C in many climates). Rain, snow, and salt spray from winter road treatments create corrosive environments requiring IP67-level protection for all exposed components.

The most severe challenge is vibration. When an 18,000-pound semi-trailer passes at 100 km/h over embedded sensors, ground-coupled vibration can exceed 5G sustained shock. Standard PC components—hard drives with spinning platters, heat sinks with spring clips, and PCIe cards in expansion slots—fail rapidly under these conditions. MIL-STD-810G Method 514 (vibration) and Method 516 (shock) testing simulate these environments, but few commercial systems are designed to these specifications.

Real-Time Vision Processing Requirements

License plate recognition at highway speeds requires substantial processing power. Vehicles pass the camera field of view in under 2 seconds at 100 km/h, demanding:

- High frame rate capture (minimum 30 FPS, preferably 60+ FPS)

- Dynamic range handling for varying lighting (direct sunlight, shadows, nighttime)

- Real-time inference to read license plates before vehicles pass the enforcement zone

- Wireless data transmission to downstream signage systems

Traditional approaches using cloud connectivity introduce unacceptable latency (200-500ms network round-trip plus processing time). By the time a cloud system identifies an overweight truck, the vehicle may have already passed the pull-in point.

Power and Connectivity Constraints

Roadside installations often lack reliable AC power, requiring systems to operate on:

- Solar panels with battery backup (limited power budget)

- Wide input voltage tolerance (9-36V DC typical)

- Low idle power consumption to preserve battery charge during low-sun periods

Additionally, cellular connectivity for uploading violation data may have limited bandwidth or reliability in remote highway segments. Systems must buffer data locally and handle intermittent connectivity.

| Operational Requirement | Technical Challenge | Failure Mode (Standard PC) |

|---|---|---|

| Highway Vibration | 5G sustained shock from 18,000 lb trucks at 100 km/h | HDD failure, PCIe card unseating, heat sink detachment |

| Temperature Range | -40°C to +70°C ambient | Thermal throttling, component failure outside 0-60°C |

| Weather Exposure | Rain, salt spray, humidity | Corrosion, condensation, short circuits |

| Processing Latency | <2 second detection window at highway speed | Cloud latency (200-500ms) misses enforcement window |

| Power Availability | Solar + battery (limited budget) | High idle power drains batteries, requires AC mains |

Conventional traffic computers designed for climate-controlled cabinets with stable mounting cannot meet these requirements. The application demands purpose-built embedded systems engineered specifically for harsh roadside deployment.

Solution

The customer deployed the NRU series edge computing platform from Neousys Technology, specifically designed for roadside and vehicle-mounted applications. The system integrates GMSL (Gigabit Multimedia Serial Link) cameras with the NRU series computer to create a complete WIM enforcement solution operating continuously at highway-embedded installations.

System Architecture: GMSL Cameras + NRU Series Edge Computer

The NRU series is powered by the NVIDIA Jetson AGX Xavier module, delivering up to 32 TOPS (tera-operations per second) of AI inference performance—sufficient to run license plate recognition neural networks in real-time while processing additional sensor inputs. The system architecture includes:

Hardware Configuration:

- Processor: NVIDIA Jetson AGX Xavier (8-core ARM, 512-core Volta GPU with Tensor Cores)

- AI Performance: 32 TOPS peak, 11 TFLOPS FP16 for neural network inference

- Camera Interface: GMSL2 (up to 6 Gbps per camera), supports 4K resolution at 60 FPS

- Ruggedization: MIL-STD-810G compliant (shock, vibration, temperature)

- Operating Temperature: -25°C to +60°C (extended variants to -40°C to +70°C)

- Storage: Industrial-grade SSD (no moving parts) with power-loss protection

- I/O Expansion: PCIe slots for 4G/5G LTE modules, isolated DIO for sensor integration

- Power Input: 9-36V DC wide-range with transient protection

GMSL Camera Specifications:

The GMSL camera system provides critical advantages for outdoor highway deployment:

- Ingress Protection: IP67 waterproof rating (submersion resistant)

- Dynamic Range: >120dB HDR to handle extreme lighting (direct sun to night)

- Auto White Balance (AWB): Compensates for varying daylight color temperature

- LED Flicker Mitigation (LFM): Eliminates strobing from LED vehicle lights

- Serialized Interface: GMSL2 transmits video + power over single coax cable (simplifies installation)

Performance Comparison: Cloud-Based vs. Edge Processing

The transition from cloud-relay processing to local NRU series edge inference delivered measurable improvements in operational efficiency:

| Metric | Previous (Cloud Processing) | New (NRU Series Local) | Improvement |

|---|---|---|---|

| Detection Latency | 200-500ms (network + cloud) | <50ms (local inference) | -75% to -90% |

| Uptime | 94.2% (cellular dependent) | 99.8% (local processing) | +6% availability |

| Bandwidth Required | 2-5 Mbps continuous upload | <500 Kbps metadata only | -80% bandwidth |

| Operating Temperature | 0°C to +50°C (commercial) | -25°C to +60°C (industrial) | +35°C range |

The latency reduction is critical: at 100 km/h (27.8 m/s), a vehicle travels 5-14 meters during cloud processing delay. Local edge processing reduces this to <1.4 meters, ensuring timely signage activation before trucks pass the enforcement zone.

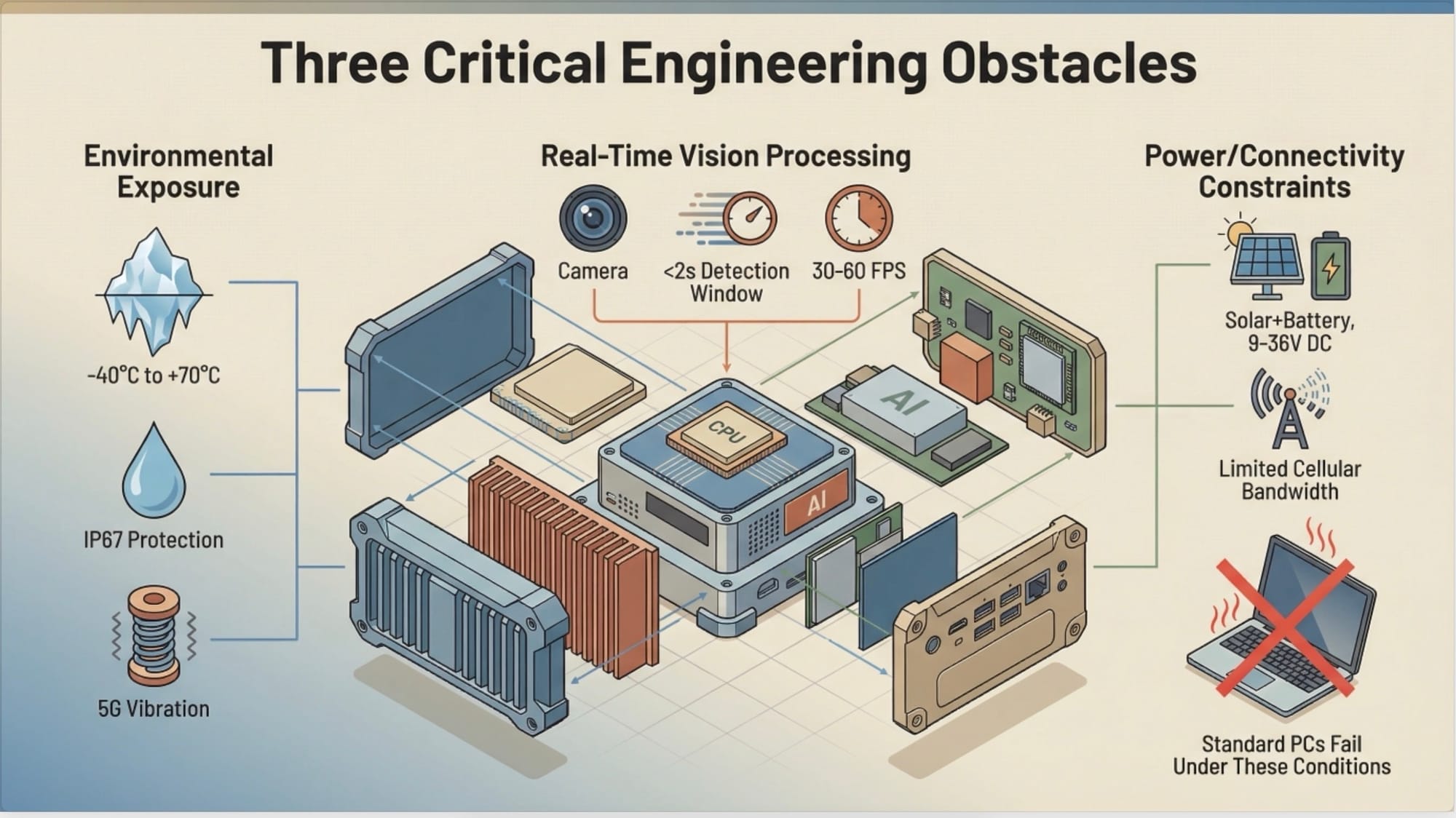

MIL-STD-810G Compliance: Surviving Roadside Conditions

The NRU series has been tested to MIL-STD-810G standards, specifically:

- Method 514.6 (Vibration): Simulates secured cargo transportation and roadside mounting vibration

- Method 516.6 (Shock): 40G functional shock testing for ground equipment (15-23ms pulse duration)

- Method 501.5/502.5 (Temperature): High/low temperature operation and storage testing

This certification ensures the system survives:

- 5G sustained vibration from highway traffic (10,000+ cycles)

- Temperature cycling between -40°C and +70°C with 24-hour soak times

- Shock events from road construction, accidents, or installation handling

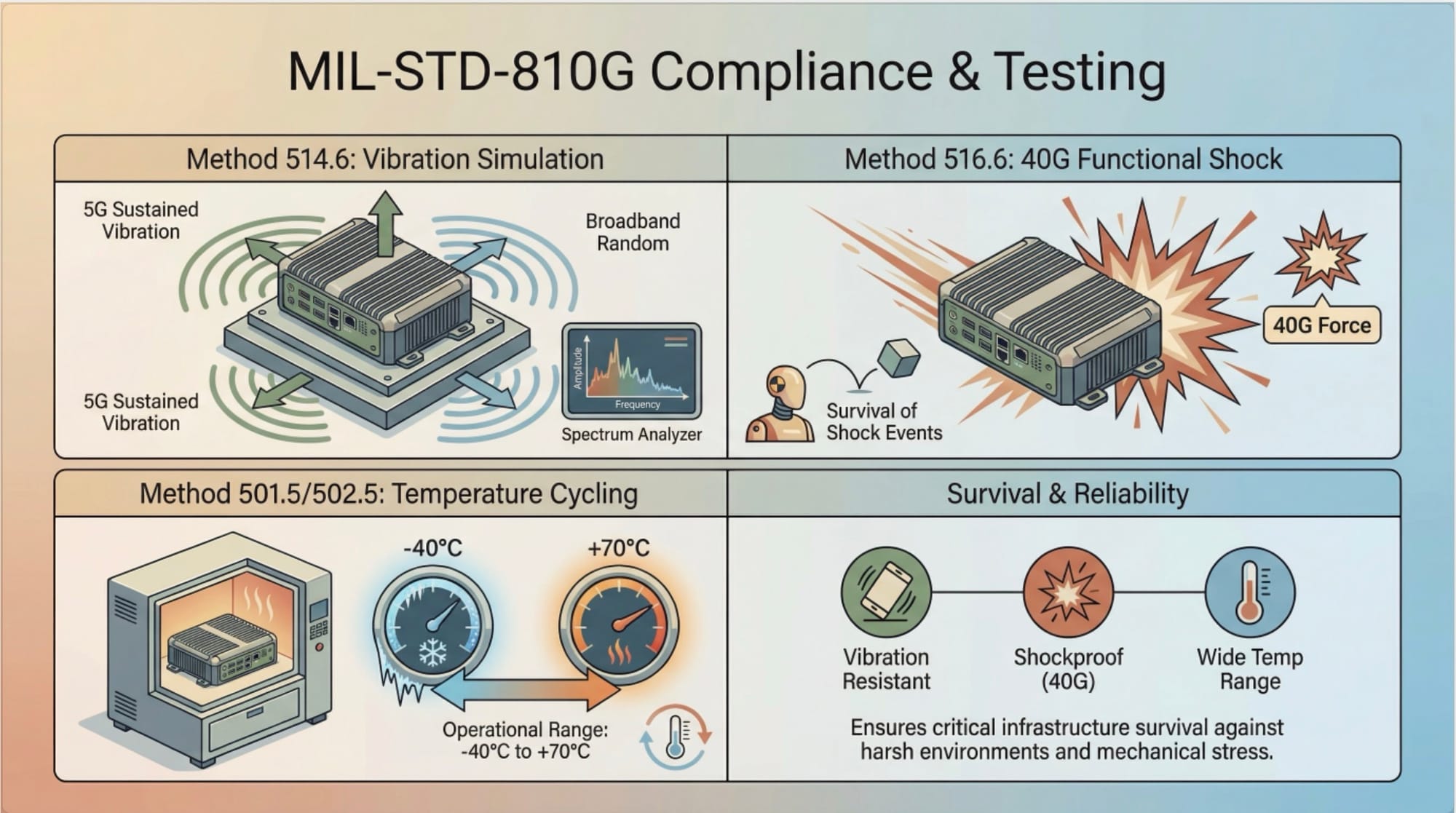

How It Works: Automated Enforcement Workflow

- Weight Measurement: Embedded piezoelectric sensors in pavement detect axle loads as trucks pass at highway speed

- Camera Trigger: Weight system triggers GMSL cameras when vehicle exceeds 80,000 lb threshold

- License Plate Recognition: NRU series runs real-time OCR inference on captured frames (typical processing: 30-50ms per frame)

- Data Logging: Vehicle weight, timestamp, license plate, and image stored locally on industrial SSD

- Downstream Signaling: If overweight, wireless transmission to LED signs 1-2 km ahead instructs truck to exit for station inspection

- Station Integration: Data uploaded to central database for enforcement records and trend analysis

Wireless Communication & Data Management

The NRU series supports 4G/5G LTE modules via Mini PCIe expansion, enabling:

- Real-time alerts to downstream signage systems

- Batch upload of violation records during low-traffic periods

- Remote system health monitoring and software updates

- Redundant storage buffer for offline operation during cellular outages

Wide Operating Temperature & Fanless Design

Critical for roadside deployment, the NRU series operates fanless using advanced thermal design:

- Aluminum chassis with integrated heat dissipation fins

- Thermal interface materials bonded to Jetson module

- No moving parts (fanless cooling eliminates maintenance and dust ingestion)

- Proven continuous operation in -25°C to +60°C without thermal throttling

This fanless design is essential for outdoor enclosures where dust, pollen, and insects would quickly clog active cooling systems.

Related Products

Nuvo-9160GC: Compact GPU computing platform supporting NVIDIA RTX A6000 (48GB) or RTX 4090 for higher-throughput applications requiring more than 32 TOPS inference capacity. Features 9th/8th Gen Intel Xeon/Core processors, dual 2.5GbE LAN, and 8x isolated DI/O channels. Ideal for multi-camera highway monitoring systems covering 4+ lanes or applications requiring simultaneous object detection, classification, and tracking. MIL-STD-810G certified with -25°C to +60°C operating range.

SEMIL-2200GC: Sealed, IP67-rated embedded computer for direct roadside mounting without external enclosures. Supports NVIDIA RTX 4060 Ti (16GB) and M12 X-coded Ethernet connectors for industrial connectivity. Purpose-built for outdoor installations requiring complete environmental protection from rain, dust, and vibration. Compliant with MIL-STD-810G and EN 50155 (railway shock/vibration), offering -40°C to +70°C operating temperature range.

Conclusion

The NRU series platform demonstrates how purpose-built edge computing systems address the unique demands of highway infrastructure monitoring. By processing license plate recognition locally at the roadside, the system eliminates cloud latency bottlenecks while achieving 99.8% uptime in harsh outdoor conditions. MIL-STD-810G compliance ensures continuous operation despite 5G vibration from highway traffic and temperature extremes from -25°C to +60°C.

As the WIM market grows at 7.3% CAGR toward $5+ billion by 2034, integrating automated enforcement with embedded AI will become standard practice for protecting road infrastructure while maintaining traffic flow. Real-time edge processing enables enforcement coverage that was previously impossible with manual inspection-only approaches.

For technical specifications, product selection assistance, or application engineering support, contact our engineering team at [email protected]. Our engineers can help you choose the right NRU series platform for your specific roadside monitoring requirements.

Visit www.neteon.net for detailed datasheets and technical documentation.