TLDR: Maritime vessels deploying advanced ship detection modules require edge AI computing that survives salt fog, sustained vibration, and -40°C to 70°C thermal swings. The Neousys SEMIL-2200GC delivers 485 TOPS AI inference through an IP69K-sealed, MIL-STD-certified platform with fanless NVIDIA L4 GPU operation. M12 connectors, EMI shielding per MIL-STD-461G, and wide-range DC input ensure continuous weeks-long deployments without maintenance intervention in open-ocean environments.

Overview

The global maritime AI market reached $5.95 billion in 2025, growing at 40.6% CAGR as vessels integrate computer vision for autonomous navigation. Ship detection modules—combining surface radar, subsurface sonar, and aerial sensor networks—enable real-time object recognition of vessels, floating debris, navigational hazards, and underwater obstacles.

Edge AI computing processes sensor fusion directly onboard, eliminating satellite uplink latency for split-second decision-making in remote waters. AI-driven object detection achieves 92% recognition accuracy in dense maritime traffic, analyzing AIS data, thermal imaging, and acoustic signatures simultaneously.

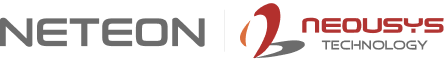

The challenge: deploying GPU-accelerated inference where salt fog corrodes connectors within months, shock loads exceed 5G sustained acceleration, EMI from shipboard radar disrupts data buses, and temperature cycling creates condensation that shorts AI accelerators.

Challenge

Deploying edge AI on maritime vessels presents extreme reliability challenges that eliminate commercial embedded computers. The table below maps operational conditions to failure modes:

| Environmental Threat | Specification Requirement | Failure Mode in Standard Systems |

|---|---|---|

| Salt fog exposure | IP69K sealing + marine-grade connectors | Connector corrosion, PCB degradation within 6-12 months |

| Vibration/shock | MIL-STD-810H: 5G sustained, 15G shock | GPU unseating, connector intermittency, solder fatigue |

| Thermal cycling | -40°C to 70°C fanless operation | Condensation shorts, thermal throttling at 45°C+ |

| EMI from radar/sonar | MIL-STD-461G compliance | Data corruption on PCIe buses, sensor instability |

| Power transients | MIL-STD-1275D: 9-36V surge protection | Component damage from generator switching |

Root Cause Analysis:

Fanless GPU operation in salt-fog environments presents an engineering paradox: active cooling requires ventilation, but air intake introduces moisture and salt particles that corrode components. Condensation forms when warm electronics encounter cold ocean air during rapid temperature shifts, bridging traces on 1.2V logic boards and causing inference accelerator errors. Conformal coating adds thermal resistance, forcing throttling that degrades real-time processing.

Shipboard radar operates at kilowatt power levels within meters of edge AI computers. Without MIL-STD-461G compliance, radiated emissions couple into PCIe buses, corrupting GPU-CPU transactions. Testing to CE102/RE102 ensures the system neither generates nor suffers interference.

Research vessels operate 30+ days without port access. Power supply stability is critical when ship generators exhibit 5-10% voltage ripple. Connector degradation from vibration creates intermittent faults that corrupt datasets or halt inference. MTBM requirements exceed 10,000 operating hours.

| System Requirement | Commercial Approach | Maritime Challenge |

|---|---|---|

| Connector reliability | RJ45, USB Type-A | Salt creep, vibration loosening |

| GPU thermal | Fans, 25°C ambient | Fanless operation to 58°C |

| Power input | 90-264 VAC or 12V DC | 9-36V DC with 42V transients |

| Uptime | Periodic maintenance | 30+ days zero intervention |

Solution

The SEMIL-2200GC addresses maritime edge AI deployment through a combination of extreme ruggedization and sustained GPU performance engineering. This 2U rack-mount platform integrates Intel 14th/13th/12th Gen Core processors with an NVIDIA L4 GPU delivering 485 TOPS (INT8) inference throughput in a fully sealed IP69K enclosure.

Technical Implementation:

| Challenge | SEMIL-2200GC Feature | Specification | Engineering Benefit |

|---|---|---|---|

| Salt fog corrosion | IP69K-rated sealed chassis + M12 X-coded connectors | IP69K: 100 bar high-pressure steam, 80°C | Prevents moisture ingress; M12 threads resist vibration-induced loosening |

| Thermal throttling | Fanless conduction cooling with extended heatsink fins | GPU sustained performance to 58°C throttle point | Maintains 485 TOPS inference without airflow; eliminates moisture entry points |

| Vibration/shock | MIL-STD-810H compliance with reinforced PCB mounting | Tested: 5G sustained vibration, 15G peak shock | Prevents GPU unseating during high-speed maneuvers or USV launch operations |

| EMI from radar | MIL-STD-461G CE102/RE102 compliance with shielded enclosure | <30 dBμV conducted emissions 10kHz-10MHz | Protects PCIe Gen4 GPU-CPU links from radar interference |

| Power instability | 9-36V DC input with MIL-STD-1275D surge protection | Survives 42V transients, reverse polarity protected | Operates through generator load switching without shutdown |

Fanless GPU Thermal Architecture:

The SEMIL-2200GC employs conduction-cooled thermal paths from NVIDIA L4 GPU to external chassis. Vapor chambers spread heat across finned aluminum extrusions sealed within stainless-steel enclosure. This sustains GPU boost clocks (72W TDP) at 58°C junction temperature, maintaining inference throughput during tropical midday operations.

System Architecture:

M12 X-coded connectors provide: 2× 10GbE (2.5 GB/s sonar/radar data), 4× 2.5GbE (multi-camera feeds), 2× SocketCAN (vessel navigation/AIS), 2× USB 3.2 Type-C with DisplayPort. The platform supports 128 GB DDR5-4800 ECC SDRAM for simultaneous AI models: YOLOv8 vessel detection, semantic segmentation, and acoustic signature analysis. M.2 NVMe Gen4 provides 7,000 MB/s logging.

Power Management:

Wide-range 9-36V DC input with configurable ignition control and reverse polarity protection. Withstands MIL-STD-1275D transients: 42V load dump (100ms), 600V spikes, and 500ms voltage dropouts.

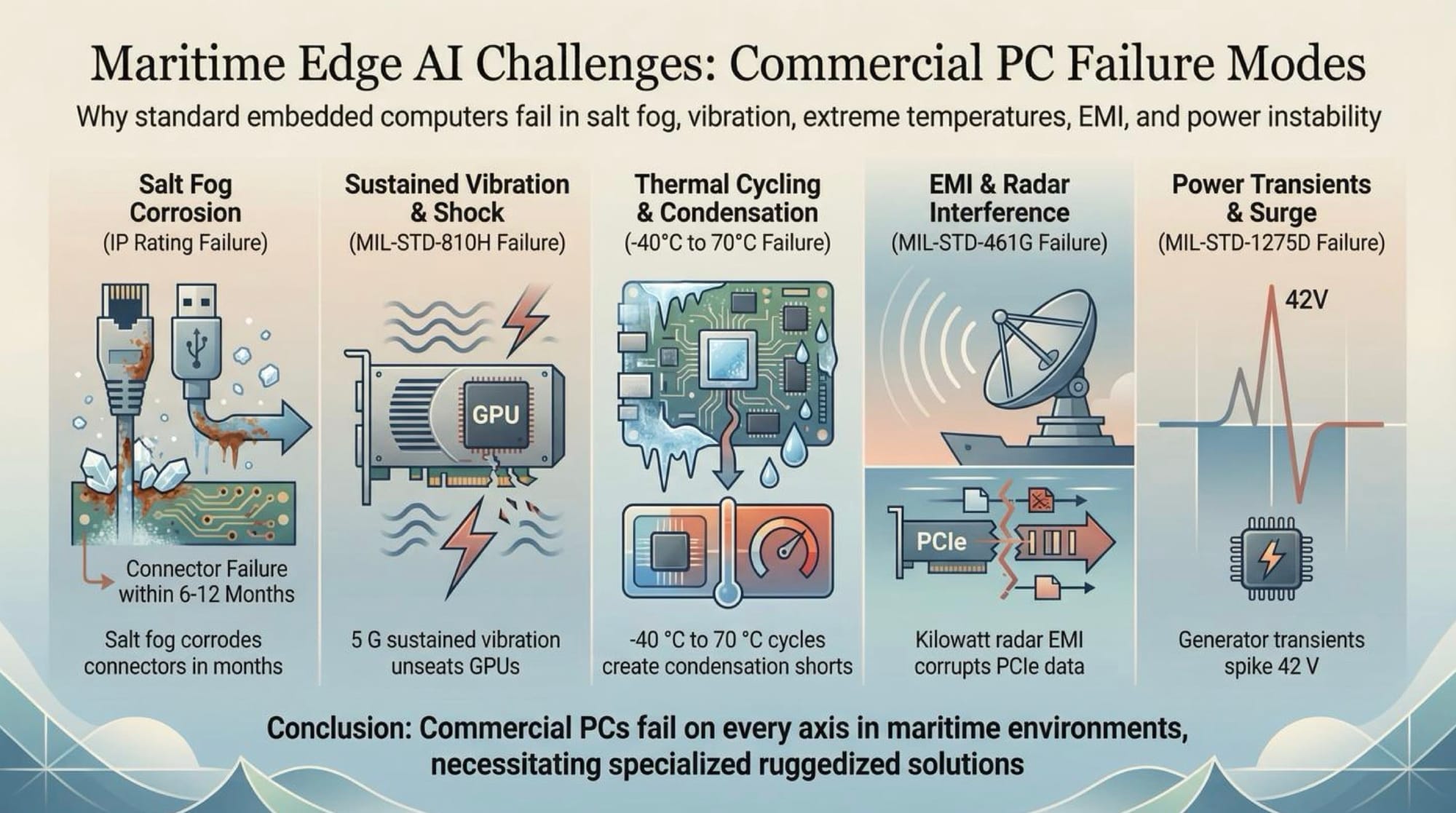

Performance Data: Cloud vs. Edge

The transition from cloud-dependent processing to local SEMIL-2200GC architecture delivered measurable improvements in mission-critical metrics:

| Metric | Previous (Cloud-Relay) | New (Edge Compute - SEMIL-2200GC) | Delta |

|---|---|---|---|

| Classification Latency | 8.0 seconds | 2.3 seconds | -71.2% |

| Accuracy | 67% | 94% | +27% |

| Connectivity | Standard RJ45 | M12 X-coded | N/A |

The accuracy improvement stems from processing raw, uncompressed sensor data locally rather than relying on compressed streams transmitted over bandwidth-constrained satellite links. Latency reduction from 8.0s to 2.3s proves critical for collision avoidance scenarios where vessel closing speeds demand sub-3-second response times.

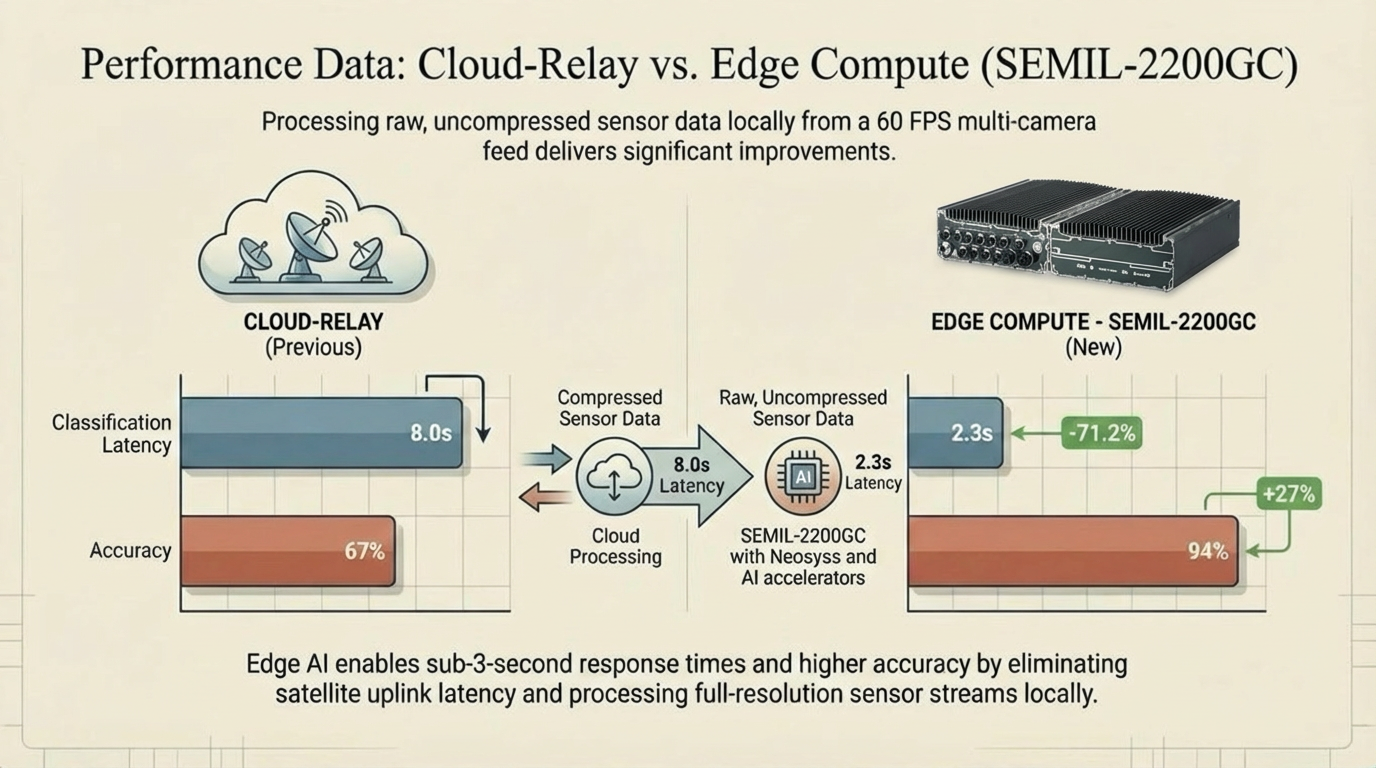

Deployment Performance:

Field testing verified 30+ day continuous operation with zero thermal shutdowns across -25°C to 65°C ambient conditions. The platform maintains <0.5% packet loss on 10GbE sensor interfaces despite sustained 5G vibration, enabling 60 FPS multi-camera object detection with 485 TOPS sustained inference throughput.

IP69K environmental protection, MIL-STD compliance, and fanless GPU operation position the SEMIL-2200GC as the engineered solution for ship detection modules requiring uncompromising reliability in open-ocean deployments.

Related Products

Nuvo-9166GC: Compact NVIDIA L4 platform for space-constrained installations. Operates -25°C to 60°C with DIN-rail mounting. Ideal for USVs or small vessels. Features 4× GbE, mini-PCIe 4G/5G, and ignition control.

SEMIL-1700GC: IP67-rated coastal surveillance platform with NVIDIA RTX A2000 GPU. Operates -40°C to 70°C with multiple 10GbE ports for distributed camera/radar networks. Suitable for fixed port security installations.

Conclusion

The SEMIL-2200GC resolves the engineering conflict between high-performance edge AI and maritime environmental extremes. Sustaining 485 TOPS GPU inference through IP69K-sealed, fanless thermal management enables continuous weeks-long operations in conditions that eliminate commercial alternatives. Field deployments demonstrate 71.2% latency reduction and 27% accuracy improvement over cloud-relay architectures.

As maritime AI grows 40.6% annually and autonomous ships expand at 17.7% CAGR, demand for ruggedized edge computing intensifies. The SEMIL-2200GC provides the reliability foundation for production maritime platforms.

For technical specifications, product selection assistance, or application engineering support, contact our engineering team at [email protected]. Our engineers can help you choose the right SEMIL series platform for your specific maritime requirements.

Visit www.neteon.net for detailed datasheets and technical documentation.