Objective: Modern smart factories deploy automated guided vehicles (AGVs) to transport machine tools between workstations and restoration areas. The challenge lies not in the physical movement but in maintaining real-time visibility across dozens of RFID-tagged tools while simultaneously coordinating AGV movements and streaming operational data to cloud analytics platforms—all within harsh industrial environments where consumer-grade hardware fails within weeks.

The engineering reality is that most industrial IoT deployments fail not because of software limitations but because the gateway hardware cannot survive the operational environment while maintaining the protocol translation capabilities that modern OT-to-IT integration demands.

Why Standard IIoT Gateways Fail in Factory AGV Deployments

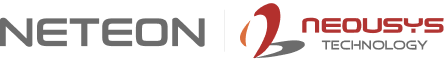

1. Protocol Fragmentation: The Modbus-to-MQTT Translation Gap

Industrial tool management systems require simultaneous communication across fundamentally incompatible protocols. RFID readers and tool sensors operate on Modbus RTU/TCP for deterministic master-slave polling, while cloud platforms demand MQTT for lightweight publish-subscribe messaging. Most deployments require external protocol converters—additional points of failure that introduce latency and complicate troubleshooting.

The Failure: Standard industrial PCs lack native Modbus support, forcing integrators to add USB-to-RS485 adapters and software conversion layers. Each adapter introduces 15-50ms latency per transaction. When polling 20+ tools at 500ms intervals, cumulative latency causes data staleness exceeding acceptable thresholds for predictive maintenance algorithms.

The Architectural Fix: Dual-Protocol Native Support

The IGT-30 Industrial IoT Gateway implements both Modbus and MQTT at the hardware level through its configurable COM port (RS-232/422/485) and dual 10/100M Ethernet interfaces.

- Mechanism: Native Modbus master functionality eliminates external converters. The ARM-based processor handles protocol translation locally, reducing round-trip latency to under 5ms per device.

- Result: Tool status updates reach cloud platforms within 50ms of RFID scan events, enabling real-time inventory tracking across the entire factory floor.

2. Environmental Survivability: The Thermal and Vibration Challenge

AGVs operate in factory environments where ambient temperatures swing from cold morning startups to 60°C+ near furnaces and welding stations. Constant motion subjects onboard electronics to persistent vibration that loosens connections and accelerates component fatigue. Consumer and office-grade hardware fails within 3-6 months in these conditions.

The Failure: Fan-cooled industrial PCs accumulate metal particulates and oil mist from machining operations. Filter clogging triggers thermal throttling, reducing processing capacity by 40-60% during peak summer months. Vibration-induced connector loosening causes intermittent communication failures that are difficult to diagnose.

The Architectural Fix: Fanless Thermal Architecture with Vibration Resistance

The IGT-30 employs a completely fanless design with passive heat dissipation through its aluminum enclosure, rated for -25°C to 70°C continuous operation.

- Mechanism: Patented damping brackets isolate internal components from AGV-induced vibrations. Solid-state construction eliminates moving parts that could fail under constant motion.

- Result: Deployed units maintain full processing capacity through seasonal temperature variations without thermal throttling or vibration-related failures.

3. Data Acquisition Density: Sensor Integration Without Expansion Hardware

Tool management systems require more than RFID communication. Presence sensors confirm tool placement, emergency stops need monitoring, and actuators control storage compartment locks. Traditional industrial PCs require expansion cards for digital I/O, increasing cost and failure points.

The Failure: Expansion-based I/O solutions consume additional power, generate heat, and introduce PCIe slot reliability concerns under vibration. Each expansion card adds potential failure modes and complicates replacement logistics during maintenance windows.

The Architectural Fix: Integrated Industrial I/O

The IGT-30 integrates eight isolated digital input channels and two isolated digital output channels directly on the main board.

- Mechanism: Optical isolation protects against ground loops and electrical transients common in industrial environments. Direct integration eliminates expansion slot dependencies.

- Result: Single-board solution monitors presence sensors, emergency stops, and tool compartment status while controlling actuators—no additional hardware required.

| Engineering Challenge | Standard Approach | IGT-30 Solution |

|---|---|---|

| Protocol Translation | External converters (15-50ms latency) | Native Modbus + MQTT (<5ms latency) |

| Operating Temperature | 0°C to 45°C (office-grade) | -25°C to 70°C (industrial-rated) |

| Vibration Tolerance | Requires external damping | Patented integrated damping brackets |

| Digital I/O | Expansion cards required | 8 DI + 2 DO integrated |

| Cloud Certification | Manual integration | Microsoft Azure + AWS pre-certified |

| Power Input | Fixed voltage | 12-25VDC + PoE powered device mode |

Implementation Checklist: AGV Tool Management Deployment

| Engineering Advantage | Implementation Consideration |

|---|---|

| Debian OS pre-installed eliminates configuration overhead | ARM-based architecture requires ARM-compatible software packages |

| WiFi and 4G cellular module options via expansion socket | Wireless modules require factory installation or field retrofit |

| CAN bus option supports AGV navigation systems | Optional CAN port requires specification at order time |

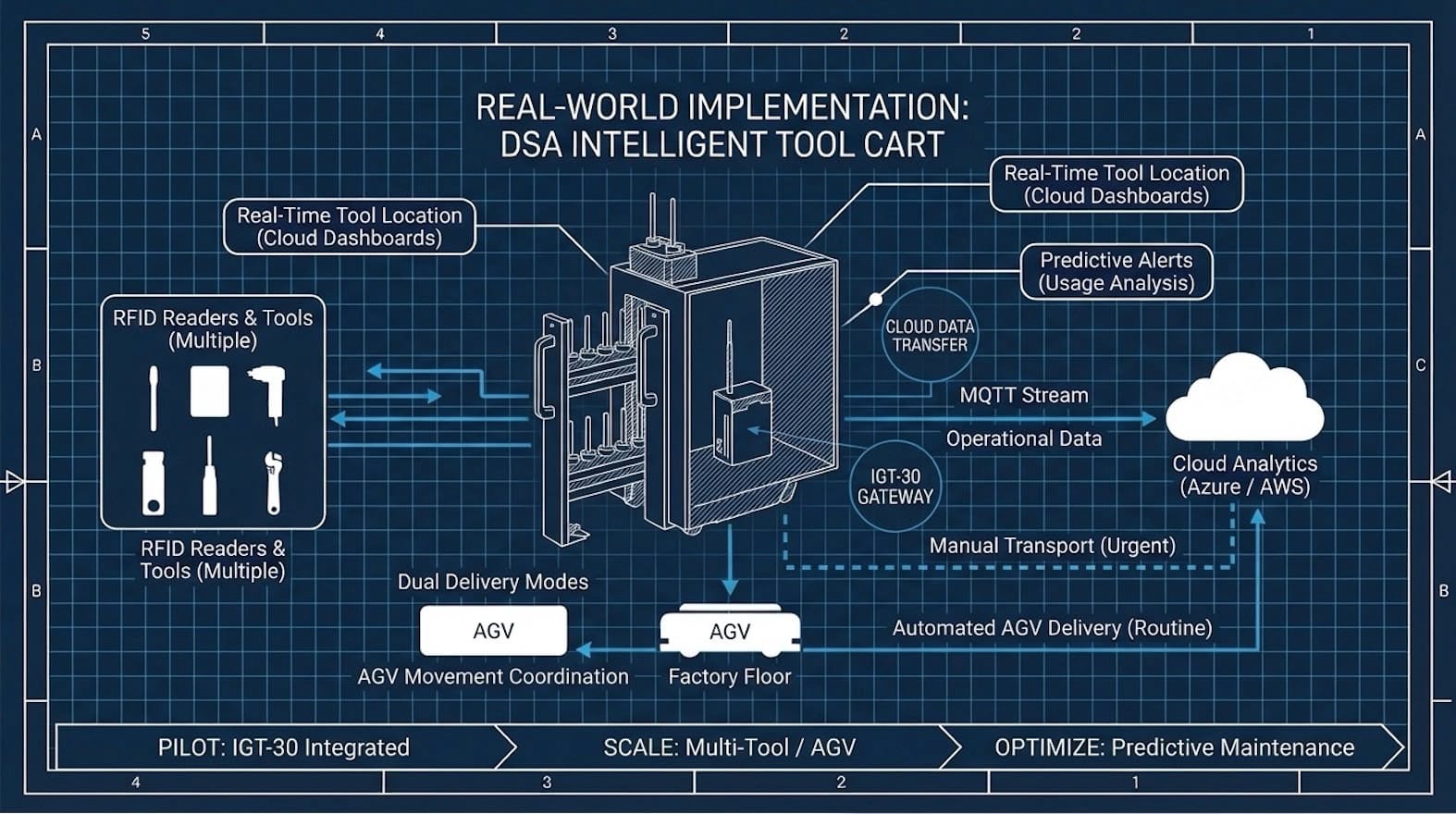

Real-World Performance: DSA Intelligent Tool Cart Integration

DSA's intelligent tool cart (DITC) deployment demonstrates the IGT-30's capabilities in production environments. The gateway simultaneously manages RFID communication with multiple tools, coordinates AGV movement commands across the factory floor, and streams operational data to cloud analytics via MQTT.

The dual delivery mode—manual transport for urgent tools, automated AGV delivery for routine restoration—operates through unified data infrastructure. Operators access real-time tool location through cloud dashboards while maintenance teams receive predictive alerts based on usage pattern analysis. Microsoft Azure and AWS certifications ensure rapid enterprise deployment.

Related Products

IGT-20 Industrial IoT Gateway: Compact gateway for simpler deployments requiring fewer I/O channels. Features 4 digital inputs, 2 digital outputs, and identical -25°C to 70°C temperature rating. Ideal for single-station tool tracking where AGV coordination is not required.

POC-551VTC In-Vehicle Computer: Ruggedized mobile computing platform for AGVs requiring higher processing power. Features Intel processor, ignition power management, and 8-35V DC input for battery-powered vehicles.

Contact Us

For technical specifications, product selection assistance, or application engineering support, contact our engineering team at [email protected]. Our engineers can help you choose the right industrial IoT gateway configuration for your specific tool management requirements.

Visit www.neteon.net for detailed datasheets and technical documentation.