TLDR: Solar farms face a critical maintenance challenge: unchecked vegetation growth reduces panel efficiency by up to 30% while creating fire hazards and equipment damage. Traditional manual weeding is labor-intensive and costly for large installations. Autonomous solar panel Weedbots powered by Neousys NRU Jetson rugged computers solve this challenge by deploying AI-driven weed detection and targeted herbicide application. These solar-powered autonomous mobile robots leverage NVIDIA Jetson computing up to 275 TOPS to distinguish crops from weeds in real time, operating reliably in harsh outdoor conditions while minimizing manual labor and maximizing solar farm efficiency.

Overview: The Growing Need for Automated Vegetation Management

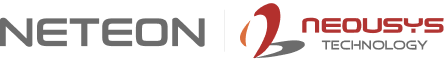

The solar panel maintenance market is experiencing explosive growth, valued at $450 million in 2025 and projected to exceed $1.34 billion by 2032 at a 14.65% compound annual growth rate. This surge reflects rapid solar installation expansion and critical maintenance demands.

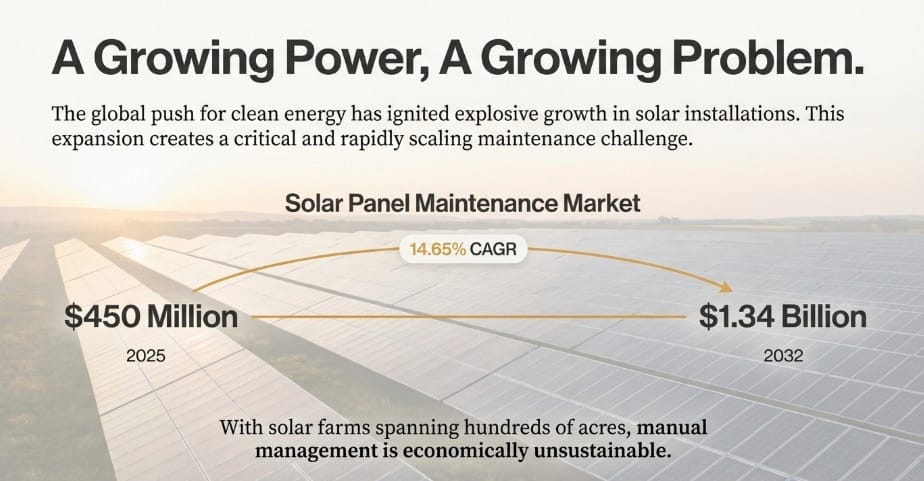

Vegetation management challenges solar farm operators significantly. Weeds and tall grasses block sunlight and disrupt electrical output—even partial shade on one panel reduces entire section performance due to series wiring. Research shows vegetation can cut solar panel output by up to 30% in high-growth regions.

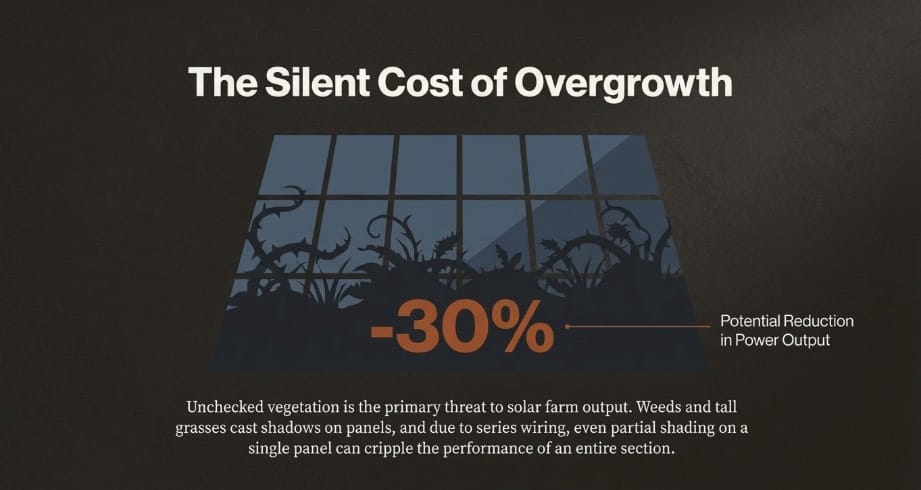

Overgrown vegetation creates fire risks during dry seasons, with dried weeds becoming dangerous fuel. Dense growth shelters rodents and insects that damage wiring and electrical enclosures, causing costly repairs. Tall grasses also obstruct maintenance access points.

Traditional control methods are inadequate. Manual mowing is labor-intensive, dangerous near panels, and risks equipment damage from debris. Conventional herbicide application lacks precision, overspraying beneficial ground cover. With solar farms spanning hundreds of acres, manual management becomes economically unsustainable. The industry requires automated solutions maintaining optimal vegetation height while operating safely across vast installations.

Why Traditional Methods Can't Keep Up

| Manual Methods | Autonomous Future | |

|---|---|---|

| Cost | High (labor-intensive) | Low (automated 24/7) |

| Safety | Low (injury & damage risk) | High (precise & automated) |

| Precision | Poor (broadcast spraying) | Excellent (targeted AI) |

| Scalability | Unsustainable (100+ acres) | Infinite (fleet-ready) |

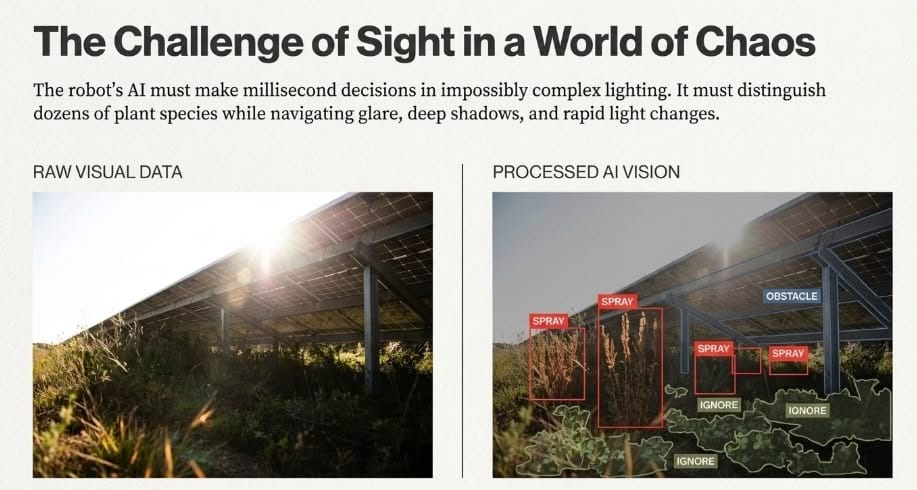

Challenge: Harsh Conditions and Complex Vision Requirements

Solar panel Weedbots face uniquely demanding environments requiring both robust hardware and sophisticated AI capabilities. Unlike indoor robots in controlled settings, solar farm robots must perform reliably outdoors while making split-second decisions affecting efficiency and environmental impact.

Environmental Extremes

Outdoor robots endure temperature swings from -25°C to 70°C across seasons and daily cycles. Solar installations occupy open land with intense sun exposure, creating thermal stress that throttles standard computing platforms. Continuous dust accumulation infiltrates electronics, while vibration from rough terrain and shock from uneven ground stress internal components. Rain, humidity, and occasional flooding introduce moisture risks causing short circuits and corrosion.

Consumer-grade platforms fail under these conditions, experiencing shutdowns, dust failures, and moisture damage. Solar operators need computing solutions specifically engineered for harsh outdoor deployment with sealed enclosures, wide temperature operation, and shock resistance.

AI Vision Complexity

Real-time visual discrimination presents the core technical challenge. Weedbots must analyze camera feeds continuously to distinguish dozens of plant species, identifying target weeds while preserving beneficial ground cover. This requires processing high-resolution imagery from multiple cameras simultaneously, running complex deep learning models, and making herbicide application decisions within milliseconds during motion.

Dynamic lighting complicates vision processing dramatically. Solar farms experience extreme lighting variations from dawn to dusk, with harsh shadows under panels, glare from reflective surfaces, and rapid changes during cloudy weather. Standard cameras struggle with extreme contrast between bright sunlit areas and shaded zones, causing misidentification. The AI system must maintain accuracy across these scenarios without constant recalibration.

Power Efficiency Demands

Extended autonomous operation demands exceptional power efficiency. Battery-powered robots need computing that maximizes AI performance per watt for multi-hour operation between charges. Solar-powered Weedbots compound this requirement—onboard solar panels must generate sufficient power for both locomotion and AI computing. High-power solutions drain batteries quickly, forcing frequent charging returns and reducing operational coverage.

Real-Time Safety Processing

Weed detection and herbicide application must occur in real time during traversal. Processing delays cause missed weeds or imprecise targeting, reducing effectiveness and wasting chemicals. The system must also identify obstacles—workers, animals, mounting structures, electrical equipment—requiring continuous detection and path planning. Latency in safety-critical functions could result in collisions or injuries.

Solution: Rugged Edge AI Delivers Reliable Outdoor Autonomy

Neousys NRU Jetson rugged computers provide the foundation for reliable solar panel Weedbot operation by combining powerful NVIDIA Jetson AI computing with industrial-grade environmental protection.

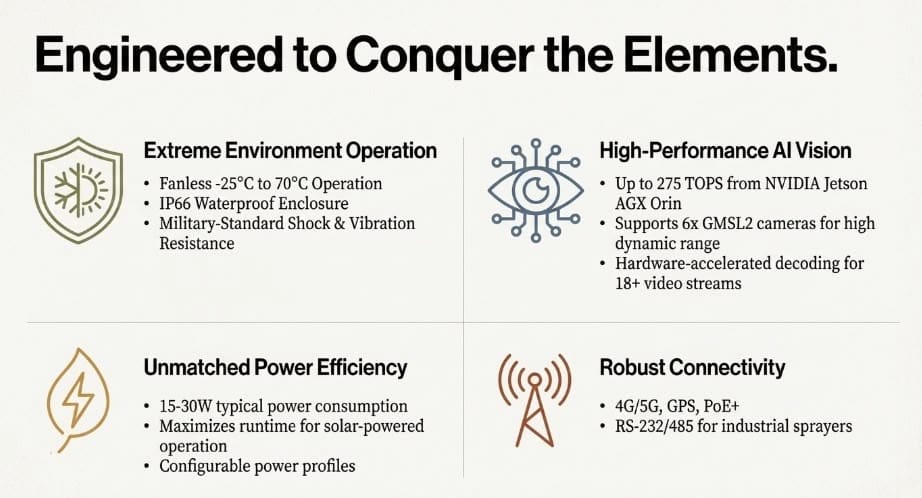

Extreme Environment Operation

The NRU Jetson series features IP66-rated waterproof enclosures protecting against dust and water, ensuring operation despite harsh solar farm conditions. Advanced thermal management enables fanless operation from -25°C to 70°C without throttling, maintaining full AI performance during extreme temperatures. Passive cooling eliminates fan failures while reducing power consumption—critical for battery-powered robots.

Shock and vibration resistance through damping brackets and screw-lock connections prevents failures during terrain traversal. The wide 8V to 35V DC input accommodates various battery configurations and voltage fluctuations during solar charging.

High-Performance AI Vision

Powered by NVIDIA Jetson AGX Orin modules, the NRU series delivers up to 275 TOPS of AI inference, enabling simultaneous processing of multiple camera feeds with complex deep learning models. This supports multi-class plant classification, distinguishing dozens of weed species from ground cover in real time.

The platform supports up to six GMSL2 automotive-grade cameras through FAKRA Z connectors, providing synchronized high-resolution 2D and 3D vision. GMSL2 cameras excel in challenging lighting, maintaining image quality across extreme contrast scenarios—from bright sunlight to deep shadows. Synchronized capture ensures temporal consistency across viewpoints, critical for 3D perception and obstacle avoidance.

Hardware-accelerated video decoding handles H.264/H.265 streams from multiple cameras simultaneously, freeing GPU resources for neural networks. The system decodes up to 18 streams of 1080p video at 30 FPS while running classification models.

Power Efficiency for Extended Operation

NVIDIA Jetson's exceptional performance-per-watt is critical for solar-powered autonomy. NRU Jetson systems operate at just 15-30 watts while delivering server-class AI performance, allowing onboard solar panels to power both locomotion and computing during daylight. This extends operational range significantly versus high-power alternatives.

Configurable power profiles balance performance with runtime. During peak sunlight with full solar charging, systems run at maximum 275 TOPS. During marginal light or battery conservation modes, power throttles to 15W while maintaining adequate inference for navigation and safety.

Robust Fleet Connectivity

The platform includes 4G LTE/5G NR cellular connectivity, enabling real-time fleet management communication in remote locations. Operators monitor robot status, receive weed detection alerts, and update AI models over-the-air. GPS integration provides precise location tracking for detailed weed distribution mapping.

Ethernet with PoE+ simplifies IP camera integration, while USB 3.2 ports enable additional peripherals like LiDAR sensors. RS-232 and RS-485 serial ports connect herbicide controllers and precision sprayers.

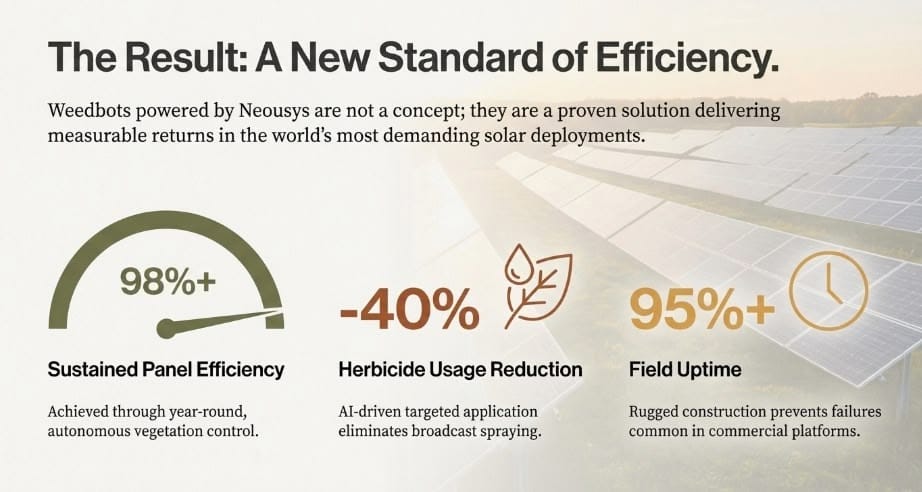

Deployment Results

Operators deploying Weedbots with NRU Jetson computing report sustained 98%+ solar panel efficiency through year-round vegetation control. AI-driven targeted herbicide application reduces chemical usage by up to 40% versus broadcast spraying. Single robots cover areas requiring multiple manual workers previously. System uptime exceeds 95% across demanding deployments, with rugged construction preventing failures common in commercial platforms.

Related Products

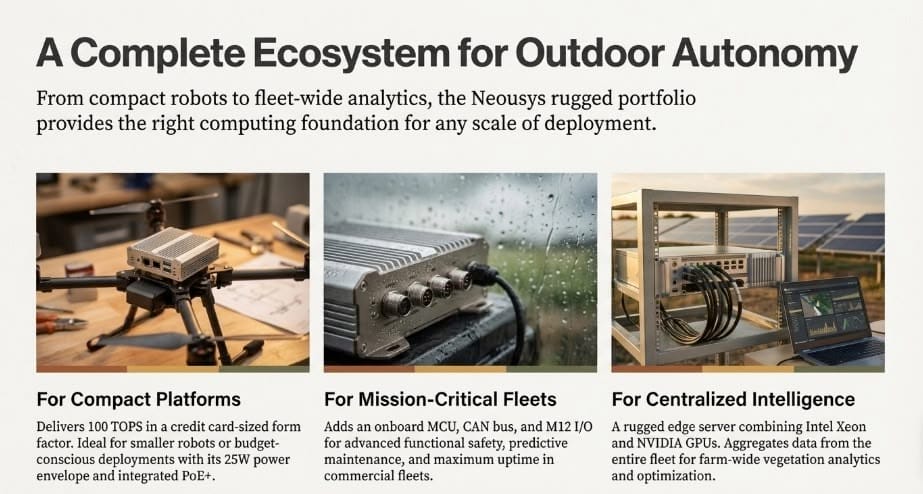

NRU-120S Series (NVIDIA Jetson Orin NX Fanless Computer):

For smaller-scale solar installations or agricultural robots requiring compact AI computing, the NRU-120S delivers up to 100 TOPS in a credit card-sized form factor. Its 25W power envelope and four PoE+ GbE ports make it ideal for budget-conscious deployments or robots with limited payload capacity, while maintaining the same rugged -25°C to 70°C fanless operation and industrial connectivity.

NRU-230V-AWP Series (IP66 Waterproof NVIDIA Jetson AGX Orin Computer):

This variant adds an onboard automotive MCU with independent M12 port for CAN bus and digital I/O, enabling advanced functional safety features and predictive maintenance for mission-critical autonomous vehicles. The integrated MCU monitors system health, controls power sequencing, and provides redundant safety channels—ideal for commercial solar farm fleets requiring maximum uptime and regulatory compliance.

Nuvo-9000 Series (High-Performance GPU Edge Computer):

For centralized solar farm monitoring stations requiring both AI inference and multi-stream video recording, the Nuvo-9000 combines NVIDIA discrete GPUs with Intel Xeon processors in a rugged fanless chassis. This platform supports 10GbE networking for aggregating data from multiple Weedbots, enabling farm-wide vegetation analytics and optimization algorithms that improve fleet coordination.

Conclusion

Solar panel Weedbots represent the convergence of autonomous robotics, AI-powered computer vision, and renewable energy—addressing critical vegetation management challenges while advancing agricultural automation. Success hinges on computing platforms that can survive harsh outdoor conditions while delivering real-time AI inference with exceptional power efficiency.

Neousys Technology's proven track record in rugged embedded systems positions the company as the trusted partner for outdoor autonomous mobile robot deployments. As solar installations continue expanding globally, the NRU Jetson series ensures that vegetation management automation keeps pace, enabling solar farms to maintain peak efficiency through intelligent, autonomous operation.

For solar farm robotics applications, technical specifications, or deployment support, contact Neousys Technology or explore solutions at Neteon.