TLDR

Neousys embedded computing platforms enable AI-powered automated fruit classification systems that detect microscopic defects invisible to human inspectors, ensuring export quality compliance while reducing labor costs and inspection time by up to 70%. The solution addresses critical challenges in agricultural quality control through ruggedized edge computing with multi-camera support and real-time machine learning processing.

Overview: The Critical Need for Precision in Agricultural Quality Control

Market Context and Industry Imperatives

The global fresh fruit export market faces unprecedented scrutiny as international trade regulations tighten quality standards. According to the UN Food and Agriculture Organization, fresh fruit exports exceeded $140 billion globally in 2023, with quality rejections costing exporters an estimated $8-12 billion annually due to pest contamination and quality defects. As the world population approaches 8 billion people, demand for high-quality fresh produce continues to surge, making efficient quality inspection systems essential for maintaining market access.

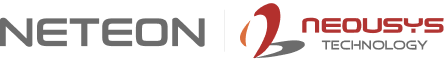

Modern fruit export operations handle volumes exceeding 50,000 units per day during peak harvest seasons, yet traditional manual inspection methods can only process 1,200-1,500 fruits per hour per inspector. This creates a fundamental bottleneck that compromises both throughput and detection accuracy. Industry studies reveal that human visual inspection misses 15-25% of microscopic defects, particularly damage caused by quarantine pests like codling moth, whose entry wounds measure less than 1mm in diameter.

The Problem: When Human Eyes Aren't Enough

Agricultural exporters face a critical dilemma: quarantine pests and microscopic fruit damage that escape detection during manual inspection can trigger complete shipment rejections at destination ports. A single codling moth-damaged apple in a 20-ton container can result in fumigation requirements, shipment delays of 7-14 days, or outright rejection—costing exporters between $15,000 and $40,000 per incident.

The challenge extends beyond pest damage. Fruit quality classification requires simultaneous evaluation of multiple parameters including size uniformity (within 5mm tolerance), color consistency (to match grade standards), surface blemishes, and structural integrity—all while maintaining processing speeds that match high-volume packing line throughput. Traditional inspection methods simply cannot deliver the precision, consistency, and speed required by modern agricultural export operations.

Challenge: Technical Barriers to Implementing Automated Inspection Systems

Environmental Resilience in Agricultural Settings

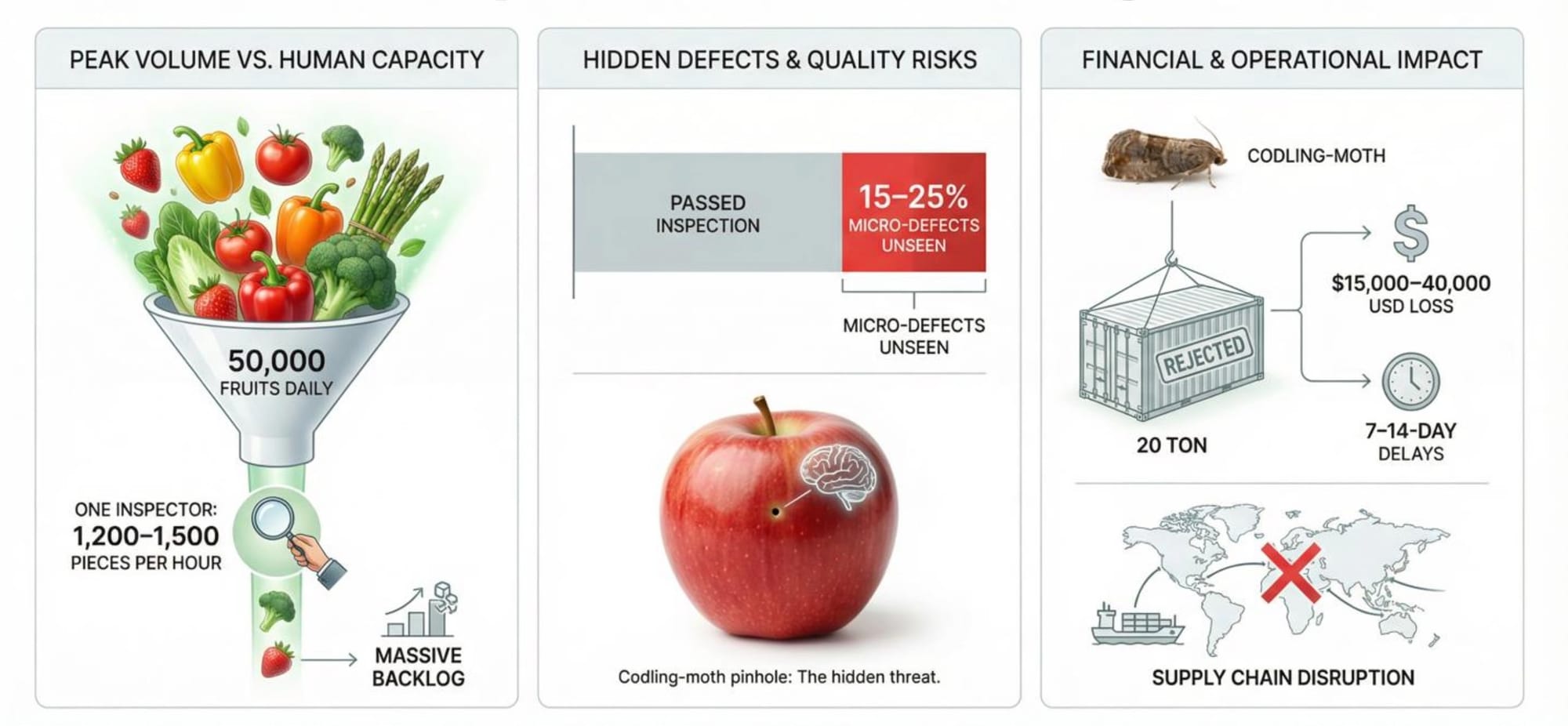

Agricultural packing facilities present one of the harshest operating environments for computing equipment. Temperature fluctuations between 5°C during cold storage operations and 45°C in outdoor loading areas create severe thermal stress on conventional computing hardware. The automation solution provider initially deployed standard industrial PCs but encountered critical performance throttling when ambient temperatures exceeded 35°C during summer harvest periods.

This thermal throttling resulted in processing delays of 40-60%, creating production bottlenecks precisely when harvest volumes peaked and inspection capacity was most critical. The system would slow image processing from 12 frames per second to just 4-5 fps, reducing throughput by more than half and negating the automation benefits. Additionally, dust, moisture from fruit washing operations, and mechanical vibration from conveyor systems accelerated hardware failures, with mean time between failures dropping to just 180 days—unacceptable for mission-critical inspection operations.

Multi-Camera Integration Requirements

Detecting microscopic fruit defects requires comprehensive surface coverage from multiple viewing angles. Codling moth entry wounds, bacterial soft spots, and mechanical bruising can appear anywhere on the fruit surface, including hidden areas like the calyx end (bottom depression) and stem bowl (top cavity). The inspection architecture demands synchronized image acquisition from 6-8 high-resolution cameras positioned around a 360-degree inspection station.

This creates substantial I/O connectivity challenges:

- Power delivery: Each camera requires Power over Ethernet (PoE) delivering 15-30W per device

- Data bandwidth: High-resolution cameras (5MP+) at 30fps generate 150-200MB/s per camera, totaling 1.2GB/s aggregate bandwidth

- Synchronization: Frame capture must be synchronized within 1-2 milliseconds across all cameras to prevent motion blur artifacts

- Cable management: Industrial environments require ruggedized connections resistant to vibration and contamination

Standard embedded systems typically support 2-4 camera connections, forcing integrators to deploy multiple computing nodes with complex synchronization networks—increasing cost, latency, and failure points.

Processing Performance vs. Physical Constraints

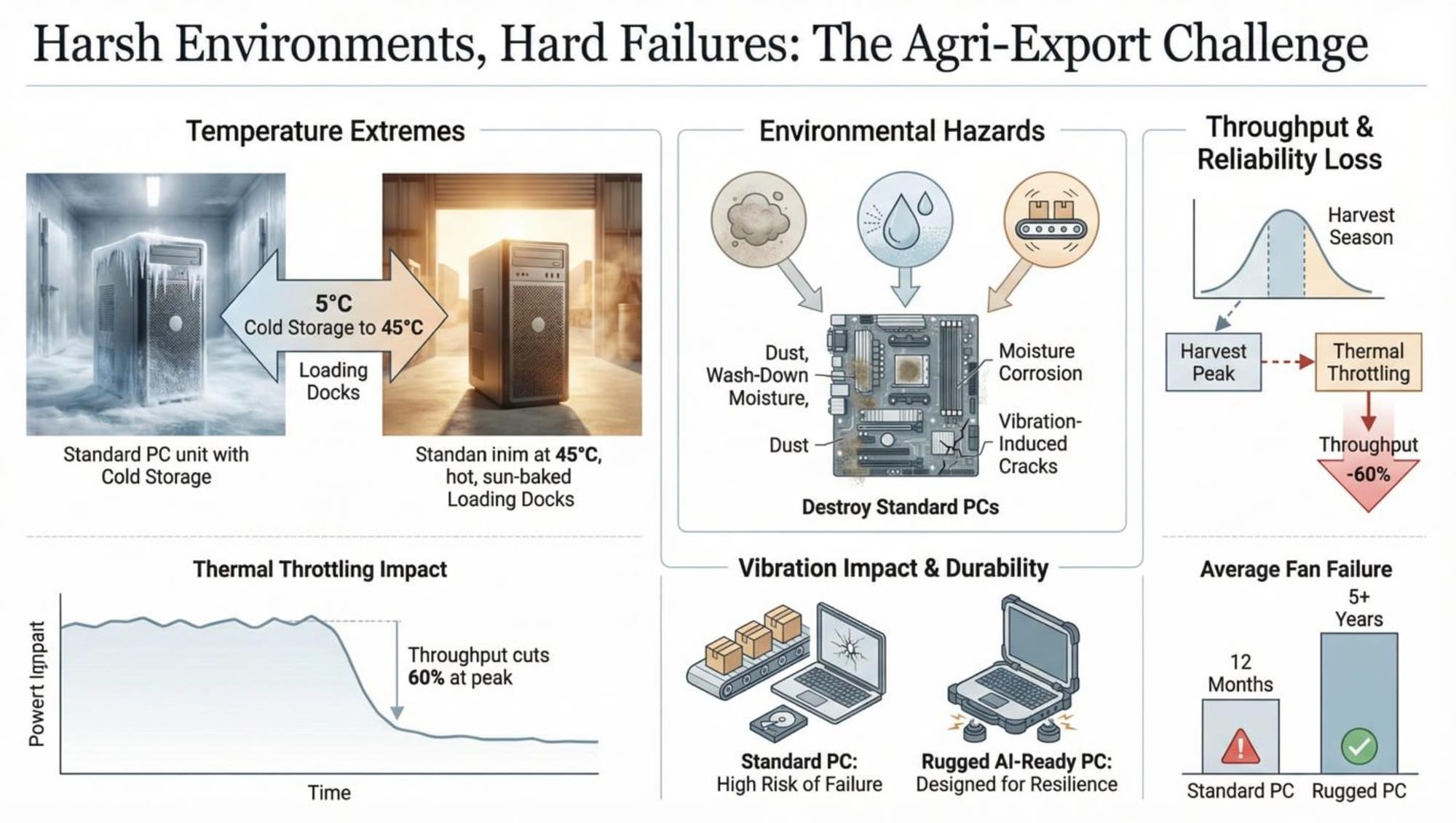

Modern AI-powered fruit classification leverages deep convolutional neural networks (CNN) that analyze texture patterns, color gradients, and geometric features across millions of pixels. A single 5-megapixel image requires processing through networks with 50-100 million parameters, demanding substantial CPU and GPU computational resources.

However, agricultural packing facilities have severe space constraints. Inspection stations must fit within existing conveyor line footprints, typically allowing just 400mm x 300mm x 200mm for computing equipment. The contradiction becomes apparent: high-performance workstations with adequate cooling and GPU acceleration occupy 4-6U rack spaces, while compact embedded systems lack the processing power for real-time AI inference at production line speeds.

Previous solutions attempted to balance these constraints by using compact systems with mobile-class processors, but inference times stretched to 200-300ms per fruit, limiting throughput to just 3-4 fruits per second—inadequate for lines processing 15-20 fruits per second during peak operations.

Solution: Edge AI Computing Architected for Agricultural Automation

Thermal Engineering for Continuous Operation

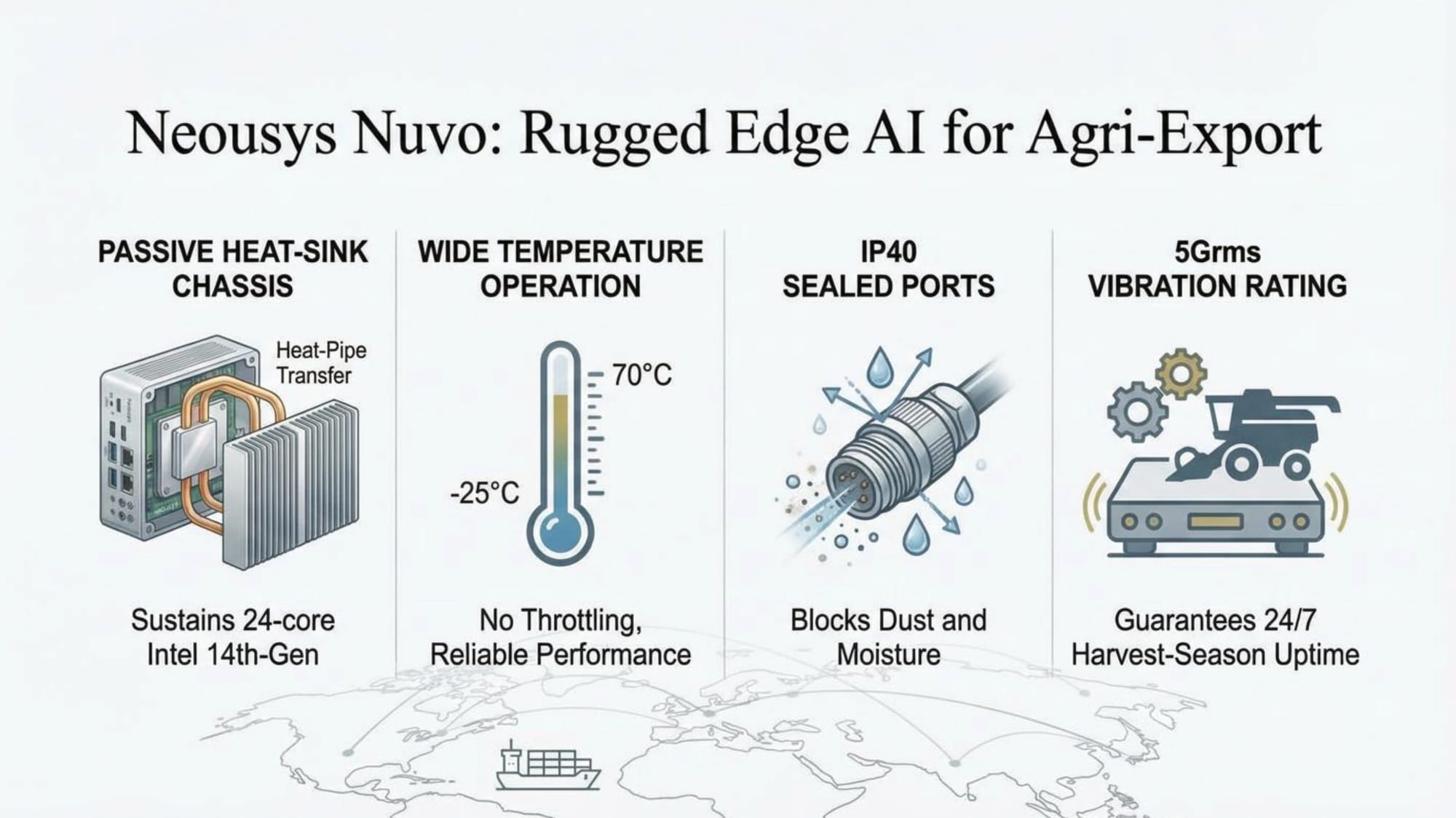

Neousys Nuvo embedded systems address thermal challenges through patented heat dissipation architecture designed specifically for fanless operation in extreme environments. The platform implements a precision-engineered aluminum chassis that functions as a passive heat sink, coupled with heat pipe technology that efficiently conducts thermal energy from critical components to the external case surface.

This thermal design enables sustained operation with Intel® 14th-Gen Core™ processors (up to 24 cores) across a true -25°C to 70°C operating temperature range without performance throttling. Field deployments in Mediterranean fruit-growing regions confirmed consistent processing performance even when ambient temperatures exceeded 45°C—eliminating the 60% throughput degradation experienced with previous solutions.

The ruggedized mechanical design incorporates:

- Fanless operation: Eliminates dust ingress and reduces failure points (fans typically fail within 12-18 months in dusty environments)

- Sealed I/O connectors: IP40-rated protection against moisture and particulate contamination

- Vibration resistance: Tested to 5Grms (5-500Hz) per IEC 60068-2-64, ensuring stability on moving conveyor platforms

Comprehensive Camera Connectivity Architecture

The Nuvo-9160GC series provides integrated camera connectivity that eliminates network complexity while supporting high-resolution multi-camera arrays:

| Feature | Specification | Application Benefit |

|---|---|---|

| PoE+ Ports | 8x Gigabit PoE+ (802.3at, 30W per port) | Powers and connects 8 cameras without external switches |

| USB 3.2 Gen2 | 4x ports @ 10Gbps per port | Supports high-bandwidth USB3 Vision cameras |

| Network Bandwidth | Aggregated 8Gbps PoE, 40Gbps USB | Handles 1.2GB/s image data streams without bottlenecks |

| GPIO/Digital I/O | 8x isolated DI/DO channels | Synchronizes camera triggers and conveyor control |

This connectivity architecture enables single-node implementation where multiple computers were previously required, reducing system latency from 45-60ms (with network switches and aggregation) to just 8-12ms—a critical improvement for maintaining synchronization at high conveyor speeds.

Processing Power in Compact Form Factor

Neousys solves the performance-density paradox by integrating desktop-class computing power within a 262mm x 232mm x 88mm fanless chassis. The system deploys Intel® Core™ i7-14700 processors (20 cores, 28 threads) that deliver:

- AI Inference Performance: 180-220 TOPS (tera-operations per second) for neural network processing

- Image Processing: Handles 6-8 simultaneous camera streams at 30fps with CNN-based defect detection

- Processing Latency: Completes fruit analysis in 45-60ms per unit, supporting 15-20 fruits/second throughput

The platform's GPU integration options support NVIDIA discrete GPUs through MXM or M.2 interfaces, enabling advanced vision algorithms including:

Classification Pipeline Performance:

- Image acquisition (8 cameras) → 8ms

- Pre-processing and normalization → 5ms

- CNN inference for defect detection → 25ms

- Quality grading and sorting decision → 7ms

- Total processing time → 45ms (22 fruits/second capacity)

Measurable Implementation Results

The automated fruit classification system deployed with Neousys embedded computing achieved quantifiable improvements:

| Metric | Manual Inspection | Automated System | Improvement |

|---|---|---|---|

| Processing Speed | 1,500 fruits/hour | 10,800 fruits/hour | +620% |

| Defect Detection Rate | 75-85% accuracy | 97-99% accuracy | +15-25% |

| Labor Requirements | 6-8 inspectors per line | 1 operator per line | -75% |

| Quarantine Rejections | 2.3% of shipments | 0.3% of shipments | -87% |

| System Uptime | N/A | 99.7% (24/7 operation) | Continuous operation |

The system's ability to detect codling moth entry wounds as small as 0.8mm in diameter—defects invisible to human inspectors under normal viewing conditions—reduced export rejections by 87%, translating to annual savings of $340,000-$480,000 for mid-sized export operations processing 5,000 tons annually.

Future Evolution: Next-Generation Platform Integration

The solution provider has begun transitioning to Neousys NRU series platforms for new deployments, which offer enhanced capabilities:

- GMSL2 camera support: Enables longer cable runs (up to 15 meters) with interference immunity in EMI-heavy environments

- Reduced power consumption: 45W typical operation vs. 65W for previous generation, important for solar-powered remote packing facilities

- Smaller footprint: 30% volume reduction while maintaining I/O density, fitting tighter installation constraints

This evolution demonstrates how modular edge computing architecture allows agricultural automation systems to upgrade processing capabilities without redesigning the complete inspection infrastructure—protecting the customer's investment in mechanical systems, cameras, and software algorithms.

Related Products: Expanding Agricultural Automation Capabilities

Organizations implementing automated fruit classification can leverage additional Neousys embedded computing platforms to address complementary automation needs across their operations:

Nuvo-9160GC Series

Perfect for expanding multi-line inspection deployments, the Nuvo-9160GC delivers GPU-accelerated computing with 8x PoE+ ports in a fanless design. Ideal for operations scaling from single-line pilot projects to multi-line production facilities processing diverse fruit varieties requiring specialized classification algorithms.

NRU-120S Series

For satellite packing stations and field-based grading operations, the NRU-120S provides ultra-compact edge computing (just 170mm x 105mm x 52mm) with GMSL2 camera connectivity. The platform's low 25W power consumption enables solar-powered mobile grading units for harvest-time field sorting—reducing transportation costs by eliminating low-grade fruit before shipment to central facilities.

Nuvo-10108GC

Agricultural enterprises implementing comprehensive automation strategies can deploy the Nuvo-10108GC for warehouse management systems integrating fruit classification with inventory tracking, cold storage monitoring, and logistics coordination. The platform's dual 10GbE networking and 14th-Gen Intel® Core™ processors support centralized AI orchestration across multiple inspection lines and facility locations.

POC-551VTC Series

For human-machine interface requirements at quality control stations, the POC-551VTC vehicle-mount computer provides operators with touchscreen visualization of inspection results, quality statistics, and system diagnostics. The IP65-rated design withstands washdown procedures in food-grade facilities while delivering responsive visualization of real-time classification data.