TLDR: A California-based automation developer needed a rugged computing solution to transform existing industrial vehicles into autonomous mobile robots (AMRs) and automated guided vehicles (AGVs). The Nuvo-8108GC edge AI platform delivered real-time processing of over 1,000 objects per second while withstanding -25°C to 60°C temperatures and 3Grms vibration. Built-in ignition control and 8-48V DC input enabled direct vehicle integration, while patented anti-vibration brackets secured NVIDIA RTX 30 series graphics cards for continuous operation in harsh mobile environments.

Overview: The Growing Demand for Autonomous Industrial Vehicles

The autonomous mobile robot and automated guided vehicle market is experiencing remarkable growth as manufacturers and logistics operators seek to automate material handling operations. The global AGV/AMR market reached approximately $6 billion in 2024 and is projected to exceed $15 billion by 2030, driven by widespread Industry 4.0 adoption across manufacturing, warehousing, and logistics sectors.

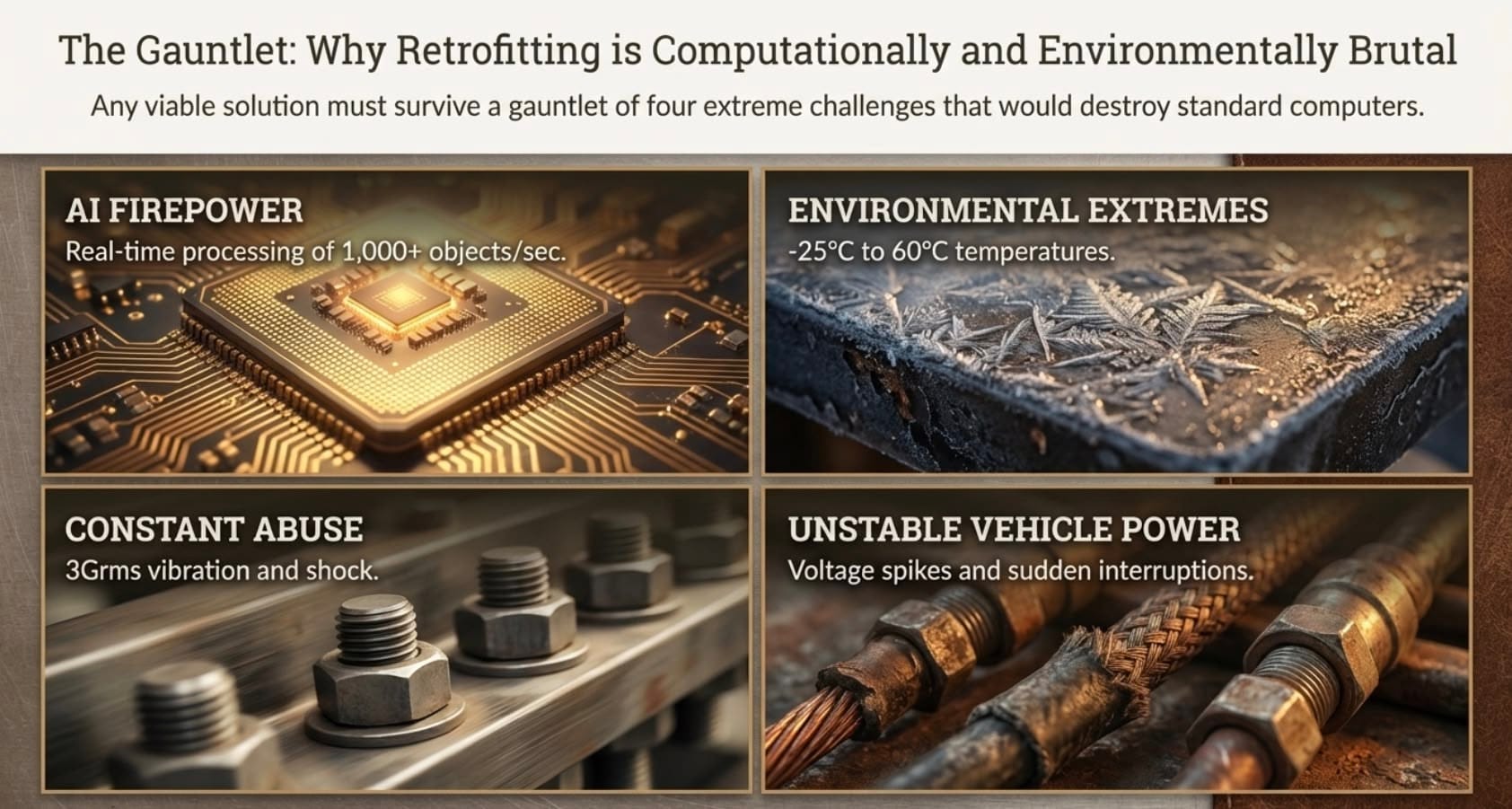

More than 200,000 AGV and AMR units were deployed globally in 2024, representing a 25% increase compared to 2022. Warehouses utilizing these autonomous systems have achieved labor cost reductions exceeding 20% while improving picking accuracy to 99.9%. The e-commerce surge has accelerated adoption further, with over 40% of logistics throughput in fulfillment centers now supported by automated systems.

However, the high cost of replacing entire vehicle fleets with purpose-built autonomous systems remains a significant barrier. Mid-sized AMR fleet installations (20-25 units) typically cost between $450,000 and $700,000, while large fleet replacements can exceed seven figures. Additionally, approximately 43% of manufacturing facilities report difficulty integrating new autonomous systems with legacy infrastructure. These challenges have created strong demand for retrofit solutions that can transform existing industrial vehicles into autonomous fleets without massive capital expenditure.

Challenge: Overcoming Retrofit Complexity and Harsh Mobile Environments

A California-based automation developer recognized an opportunity to address the market gap between expensive purpose-built AMRs and organizations' existing vehicle assets. Their vision was to create a retrofit solution that could convert conventional industrial vehicles into fully autonomous systems, enabling faster Industry 4.0 adoption at a fraction of traditional costs.

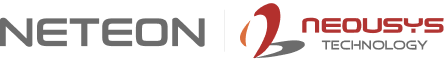

Developing this retrofit technology presented formidable challenges across multiple dimensions.

Computing Power Requirements: Real-time autonomous navigation demands simultaneous processing of data from multiple LiDAR sensors, cameras, and proximity detectors. The system needed to identify and track over 1,000 objects per second while making split-second navigation decisions. Consumer-grade or office computing hardware lacked the GPU acceleration required for these intensive AI inference workloads.

Extreme Environmental Conditions: Industrial vehicles operate in environments far outside typical computing parameters. Warehouse loading docks experience temperature swings from freezing winters to scorching summers. Manufacturing floors generate constant vibration from heavy machinery. Dust, debris, and occasional impacts are unavoidable realities. Standard computing equipment would fail within weeks under these conditions.

Vehicle Power Integration: Unlike stationary equipment with stable power supplies, vehicle-mounted systems must contend with electrical irregularities. Engine startup produces voltage spikes that can damage sensitive electronics. Sudden power interruptions during vehicle shutdown risk data corruption and system failures. The solution required power management designed specifically for mobile deployment.

Wireless Connectivity Demands: Fleet management and real-time data transmission require robust wireless communication capabilities. The system needed expansion options for WiFi 6, 5G/4G cellular modules, and other connectivity solutions while maintaining reliable operation in RF-challenging industrial environments.

Previous computing solutions forced unacceptable compromises. Industrial-grade systems often lacked sufficient GPU performance for AI workloads. Consumer GPU workstations couldn't survive the environmental extremes. The retrofit solution demanded a platform that eliminated these trade-offs entirely.

Solution: Nuvo-8108GC Edge AI Platform Powers Autonomous Retrofits

The Nuvo-8108GC from Neousys Technology emerged as the definitive computing platform for this demanding retrofit application. Purpose-built for GPU-accelerated edge AI in mobile environments, the Nuvo-8108GC addressed every technical challenge while enabling straightforward vehicle integration.

High-Performance GPU Computing: The Nuvo-8108GC supports NVIDIA RTX 30 series graphics cards delivering up to 14 TFLOPS of FP32 computing power. This performance enables real-time processing of sensor data from multiple cameras and LiDAR units simultaneously. The system processes over 1,000 objects per second, providing the computational foundation for autonomous navigation, obstacle avoidance, and path planning.

Industrial-Grade Thermal Design: Neousys' patented heat dissipation technology enables continuous -25°C to 60°C operation without CPU or GPU throttling. The sealed thermal tunnel exhausts hot air while drawing cool air from outside the enclosure. This design ensures consistent AI inference performance regardless of ambient conditions, eliminating the thermal-induced performance degradation common in standard computing hardware.

Vibration and Shock Protection: The Nuvo-8108GC incorporates patented damping brackets and a proprietary GPU press bar that secure the graphics card against vibration up to 3Grms. This MIL-STD-810G compliant protection prevents component damage and maintains signal integrity during vehicle operation across rough floors, over expansion joints, and through the inevitable jolts of industrial environments.

Vehicle Power Management: Wide-range 8-48V DC input accommodates direct connection to vehicle electrical systems without external power conversion. Built-in ignition control sequences system startup and shutdown with vehicle operation, preventing damage from voltage spikes during engine start. SuperCAP UPS technology provides graceful shutdown protection during unexpected power interruptions, safeguarding data integrity and system state.

Scalable Connectivity and Expansion: Beyond the primary x16 PCIe slot for GPU installation, the Nuvo-8108GC provides additional x8 and x16 PCIe expansion slots for data acquisition, analytics, and communication cards. M.2 and mini-PCIe slots enable integration of WiFi 6 and 5G/4G cellular modules for fleet connectivity. USB 3.1 ports with screw-lock mechanisms ensure reliable camera connections despite vibration.

The retrofit solution built on the Nuvo-8108GC platform transforms implementation timelines from months to hours. Vehicles retain their operational value while gaining autonomous capabilities, reducing deployment costs by eliminating the need to purchase entirely new AMR/AGV fleets. Fleet operators gain edge AI analytics for operational insights, safety improvements through reduced human-vehicle interaction, and labor cost reductions that address persistent workforce challenges.

Related Products

- Nuvo-8108GC-XL (Extended GPU Platform):

- Why it Complements: For retrofit applications requiring maximum AI inference performance, the Nuvo-8108GC-XL accommodates larger NVIDIA RTX 30 series cards including the RTX 3080. The extended chassis maintains identical rugged characteristics while delivering enhanced computing power for complex multi-sensor autonomous systems.

- Link: https://www.neteon.net/products/product/5/nuvo-8108gc-xl-series

- Nuvo-8108GC-QD (Professional GPU Platform):

- Why it Complements: Supporting NVIDIA RTX A6000 and A4500 professional graphics cards, the Nuvo-8108GC-QD targets AI development, training, and high-precision inference workloads. Professional GPU support enables advanced simulation and model refinement for autonomous navigation algorithms.

- Link: https://www.neteon.net/products/product/5/nuvo-8108gc-qd-series

- NRU Series (NVIDIA Jetson Platform):

- Why it Complements: For smaller autonomous vehicles or applications where power consumption is critical, the NRU series delivers edge AI capabilities through NVIDIA Jetson modules. The compact fanless design suits space-constrained installations while maintaining industrial-grade ruggedness.

- Link: https://www.neteon.net/products/product/5/nru-series

Conclusion

The autonomous retrofit solution powered by the Nuvo-8108GC demonstrates how industrial-grade edge AI computing transforms Industry 4.0 adoption economics. Organizations gain autonomous fleet capabilities without discarding vehicles with remaining operational lifespans, achieving automation goals at a fraction of traditional AMR/AGV investment.

Neousys Technology's combination of high-performance GPU computing, proven thermal management, and vehicle-grade power handling positions the Nuvo-8108GC series as the foundation for demanding mobile AI applications. As autonomous industrial vehicles continue reshaping manufacturing and logistics operations, Neousys remains committed to advancing rugged edge computing platforms that bring AI from laboratories into real-world deployment.

For technical specifications, integration guidance, or retrofit application support, contact Neteon at https://www.neteon.net/ or visit Neousys Technology at https://www.neousys-tech.com/